Menu • Quick Links • Search

Login

CloseMore than two hundred years ago, South Carolinians dreamed of utilizing the Santee and Cooper rivers to improve the economic condition of the coastal plain. The proposed canal would funnel produce from the growing interior regions of the two Carolinas through the port of Charleston. Along the route of the canal, towns would spring up, attracting new settlers and increasing land values. The project was finally complete and actively delivering power to local companies in 1942. By the 1970’s the original vision had become reality as dozens of manufacturing plants were attracted to the region by inexpensive electricity, water access and a stable labor force.

Similar to the zinc patina, some waters allow the zinc coating to develop a passive film on the surface slowing the rate of corrosion.

The South Carolina Public Service Authority (Santee Cooper) is South Carolina’s state-owned electric and water utility that was created during the New Deal. They were the driving force behind the successful completion of this expansive project. They created two lakes (Marion and Moultrie) and cleared large tracks of land while building hydro-electric dams and power plants. Today, they provide power to more than 165,000 residents and commercial customers in Berkeley, Georgetown and Horry counties.

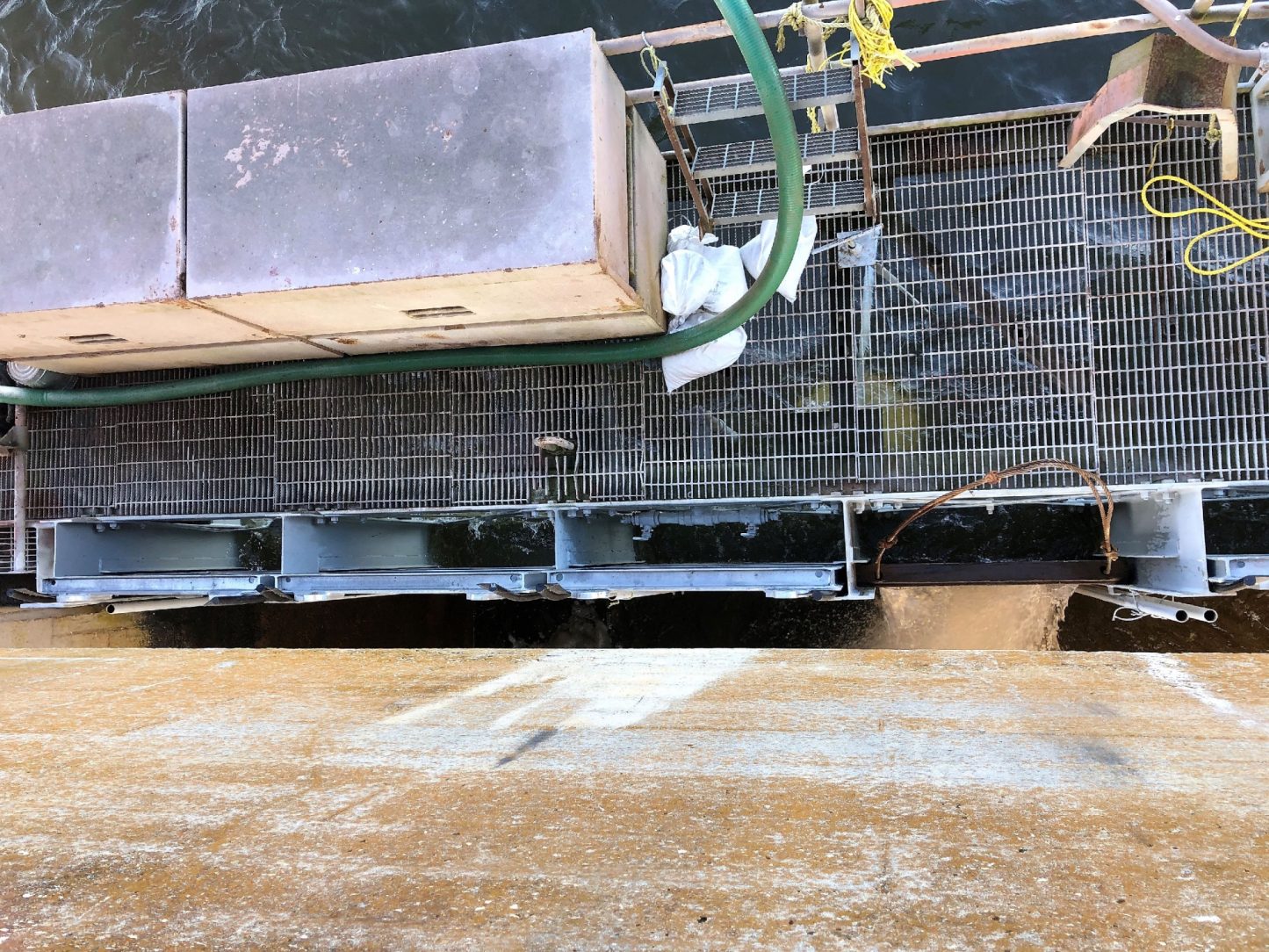

On the Santee River, an 8-mile long earthen dam with 3,400-foot spillway was the longest in the world at the time it was constructed. The concrete spillway contains 62 gates measuring 14’ x 50’ with stoplogs to control the floodwaters. Stoplogs are hydraulic engineering control elements used in floodgates to adjust the water level or discharge in a river, canal or reservoir. As individual stoplogs begin to age, they leak and require replacement. Although some water typically leaks between individual logs as they age, there was a particular area that recently became a steady stream due to excessive decay of the timber. As it was threatening to erode the earthen face of the downstream side of the dam, a replacement was necessary.

Stoplogs are typically long rectangular timber beams or boards that are placed on top of each other. Since the height of the barrier can only be adjusted through the addition or removal of stoplogs, finding a lighter and stronger material other than wood or concrete became a desirable improvement. After reviewing the available options, galvanized steel was selected as the replacement solution for this project.

Project engineers understood the harsh environment the stoplogs would be placed in. The replacements needed to be able to withstand constant exposure to water without deterioration. The complete and uniform coverage of hot-dip galvanizing protects steel submerged in water. Similar to the zinc patina, some waters allow the zinc coating to develop a passive film on the surface slowing the rate of corrosion. The successful track-record of using hot-dip galvanized steel on dams, docks and piers over several decades helped assure Santee Cooper that galvanized steel would be a long-lasting and reliable solution.

Another important consideration for the replacement stoplogs was the impact to aquatic life. Striped Bass fishing is a major recreational activity along the rivers and in Lake Marion and Moultire. Sizeable fish catches attract tourists from around the country so maintaining this coveted activity was extremely important to the community. Any replacement solution would need to guarantee there wouldn’t be any negative impacts to the fish population. The selection of hot-dip galvanized steel lives up to that promise because zinc already exists naturally in the water. Galvanized steel does not expose the environment to any man-made chemicals or other pollutants.

According to ASCE’s Report Card for America’s Infrastructure, most of our water infrastructure is in serious need of repair and upgrading. We now have better materials available than we did when these structures were first constructed. With decades of case studies supporting longer life spans and improved sustainability, hot-dip galvanized steel provides durability, longevity, and cost effectiveness to improve the water infrastructure now and in the future.

Details

Award Class

Newly Complete

Award Sectors

Water & Marine

Environment

Temperate Marine

Location

Pineville, SC United States

Reasons for Galvanizing

Coating Durability, Corrosion Performance, Life-Cycle Cost, Quality of HDG, Sustainability

Components Galvanized

Twelve 24’ x 4’ spillway frames/stoplogs

Tonnage/Size

Steel: 13

HDG: 13

Team Members

Owner

Santee Cooper

Member Galvanizer(s)

Valmont Coatings - Columbia Galvanizing

Thank you! Your vote has been accepted.