Menu • Quick Links • Search

Login

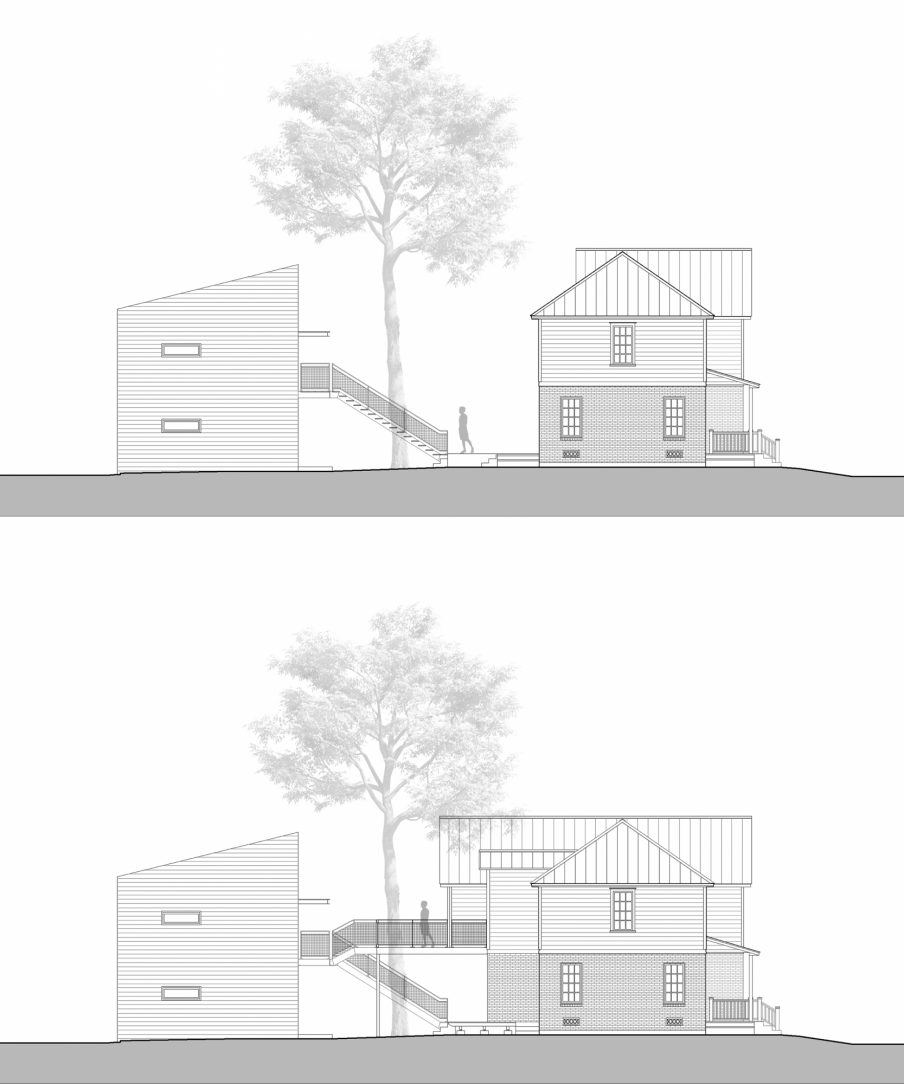

CloseThe Skywalk Addition blends together two separate spaces: a traditional single family home built in 1930 and a modern artist studio built in 2001. The owners, both artists, are approaching retirement and wanted to build a structure to span from house to studio, like a bridge, to provide accessibility to their studio into old age. The style of the Skywalk was driven by the existing galvanized entrance to the studio, designed in 2001 by Ronnie Self, Architect.

In this project, we used galvanized steel to create a civic-quality structure in the backyard of our client.

The owners required that our design incorporate materials and processes that are sustainable, maintenance-free, and locally sourced. In the addition we reused original (and salvaged locally) bricks, doors, trim, and wood floors. Hot-dip galvanizing provided the ideal coating for the Skywalk structure due to its low maintenance, modern look, and subtle color and pleasing aesthetics when paired with the soft red and brown tones of the bricks and wood at the addition.

I received a call from a potential client: she said, "It's hard to explain but I want to make a bridge from my house to my garage studio." I expected that this was a call from a client describing a fantasy that would be crafted into a reasonably typical remodel situation. It turns out this was a reasonable client who happened to deliver a fantasy project for the designer and builder.

The client had built a secondary structure, a garage/art studio, in 2001. At our first site visit we were blown away by the hidden modern gem behind an unassuming traditional single-family house. The architect of the modern studio had used hot-dip galvanized steel to create a striking entrance to the second floor of the structure. It was clear that to blend the two spaces hot-dip galvanized steel would be a major element of the design. The existing steel had no rust and looked like it had been there forever and would continue to do so.

Hot-dip galvanized steel is a foundation of the landscape in this city. Living in an urban area so close to heavy industry creates an opportunity to use hot-dip galvanizing in atypical applications. In this project, we used galvanized steel to create a civic-quality structure in the backyard of our client.

We created removable deck frame modules to be topped with Pressure Treated Pine (2x12) and to fit between C-channel beams which span from 4"x4" galvanized posts in the back yard to the wood frame house. The removable steel deck frame was made by sandwiching split wide flange beams (to create a T-Shape profile) between 1/2" x 8" plate. The assembly was bolted between beams to allow removal for galvanizing. The guardrail was bolted down to beams as well to allow removal for galvanizing. We fabricated the guardrail (3/4"x2" bar and 2"x2" livestock fence) to match the existing stair guardrail (designed by Ronnie Self in 2001).

By installing new hot-dip galvanizing to pair with 15-year-old galvanized steel, we were confident the two structures would patina together perfectly with little to no maintenance for decades.

Details

Award Class

Newly Complete

Award Sectors

Building & Architecture

Environment

Industrial/Urban

Location

Houston, TX United States

Reasons for Galvanizing

Aesthetics, Coating Durability, Corrosion Performance, Life-Cycle Cost, Prior HDG Experience, Quality of HDG, Sustainability

Components Galvanized

Removable deck frame modules, C-Channel beams, galvanized posts, deck frame (split, wide-flange beams in T-shape), bolts, guardrail, wire fence

Tonnage/Size

Steel: 3

HDG: 2

Team Members

Others

Hokyung Lee

Color Houses

Zach Haines

Color Houses

Engineer

Brad Dougherty

Insight Structures

Fabricator

Esdras Davila

Davila Fence and Welding

Member Galvanizer(s)

Valmont Coatings - United Galvanizing

Thank you! Your vote has been accepted.