Menu • Quick Links • Search

Login

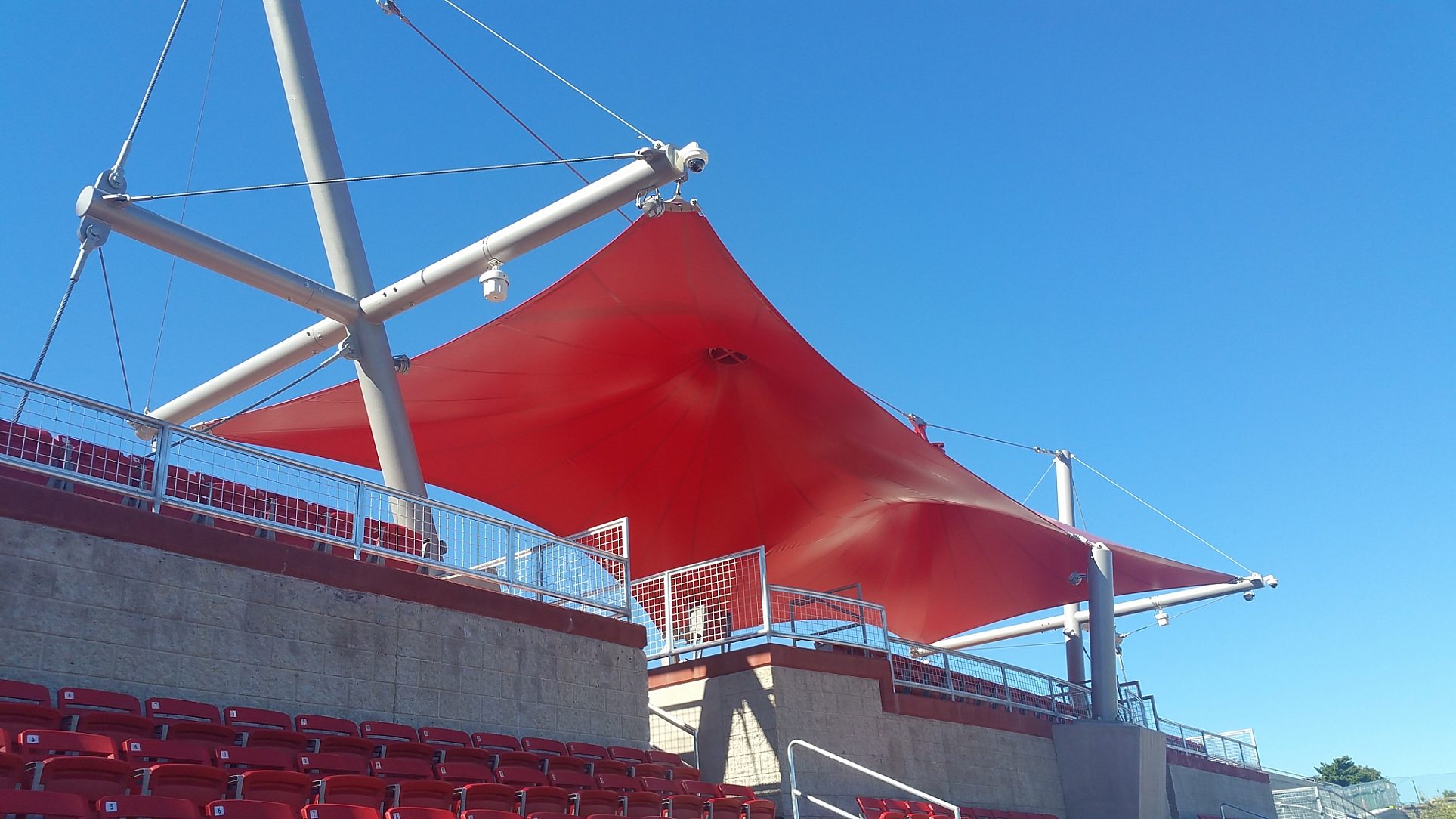

CloseMaryville University is a moderate sized institution 22 miles from Downtown St. louis that was founded in 1872. when the University decided to give their outdoor facility, used for Soccer and Lacrosse, and the bare grassy hill used for spectating an upgrade, the task of creating a unique, yet functional shade/canopy was given to Lawrence Fabric and Metal Structure's in St. Louis, MO. The end result is a tension structure that not only catches the eye but provides the press area with a shaded spot to catch and call all the action.

“Our university has grown, and we try to be very strategic with how we add value for the student population,” Lonnie Folks, director of Maryville’s athletics and recreation

In 2016, Maryville University started construction on multiple sports fields on their main campus in St. Louis, MO. The shared soccer and lacrosse field was the first to be completed. In 2018, Maryville University continued upgrading the field by adding stadium seating and constructed a new track encircling the soccer/lacrosse field. The stadium seating included a large canopy to provide shade for the press area. Lawrence Fabric and Metal Structure's took on the challenge to create this structure.

The 14,000 pound structure was first hot-dipped galvanized to ensure that it was protected from corrosion due to all of the elements that Mother Nature could throw at it. By doing so, the life expectancy of this fantastic structure should last for many graduating classes to come. The tension structure was brush blasted and powder coated for the ideal finish and curb appeal, as well as adding an extra layer of protection. The design was finished off with the customary Maryville Saints red canopy. The end result is an imaginative mix of creativity, sustainability, and aesthetics that are sure to be the talk of all who view it (including rival schools). It was important to the university to have the protection galvanizing can provide, as well as the display the school colors. It was a perfect solution to achieve protection, longevity and appearance they wanted.

In addition to the tension structure, galvanized handrail and guardrail were used for the surrounding area and bleachers below. Murray Enterprises in Perryville, MO was tasked with this project and they stepped up to the challenge and created a system of rails that are not only functional, but, due to their unique design, also add to the overall visual appeal of this project.

With its top-notch fabricated parts and superior duplex coating – Maryville University has given their facility a face-lift that will not only last for many years to come but will also give their fans a place to cheer on their beloved Saints for many generations to come. Go Saints!

Details

Award Class

Newly Complete

Award Sectors

Recreation & Entertainment

Environment

Suburban

Location

St. Louis, MO United States

Reasons for Galvanizing

Aesthetics, Coating Durability, Corrosion Performance, Sustainability

Components Galvanized

All structural pieces to the tension structure and all hand and guard rail.

Tonnage/Size

Steel: 13

HDG: 13

Team Members

Fabricators

Lawrence Fabric and Metal Structure's

Murray Enterprises

Member Galvanizer(s)

AZZ Galvanizing - St. Louis

Thank you! Your vote has been accepted.