Menu • Quick Links • Search

Login

CloseThe Collins Park Water Treatment Plant is responsible for the effective production, filtration, and quality control of water for the City of Toledo. The Division's responsibility starts at the source of raw water, Lake Erie, and extends throughout the treatment process. This Division operates and maintains the largest softening plant on Lake Erie. Filtering an average of 75 million gallons of water per day is a monumental task.

Water is life's matter and matrix, mother and medium. There is no life without water.

At no time in the process is the water allowed to stop moving. Every area within the plant can be isolated, so maintenance or repairs can be made without affecting the flow or quality of the water produced. The Toledo Water Treatment Plant is known not only for quantity and quality of water produced, but also for its staff's dedication to implementing improvements in both testing and treatment of water. It is for these reasons that many suburban communities purchase water from Toledo, and why many businesses choose to locate in the Toledo area.

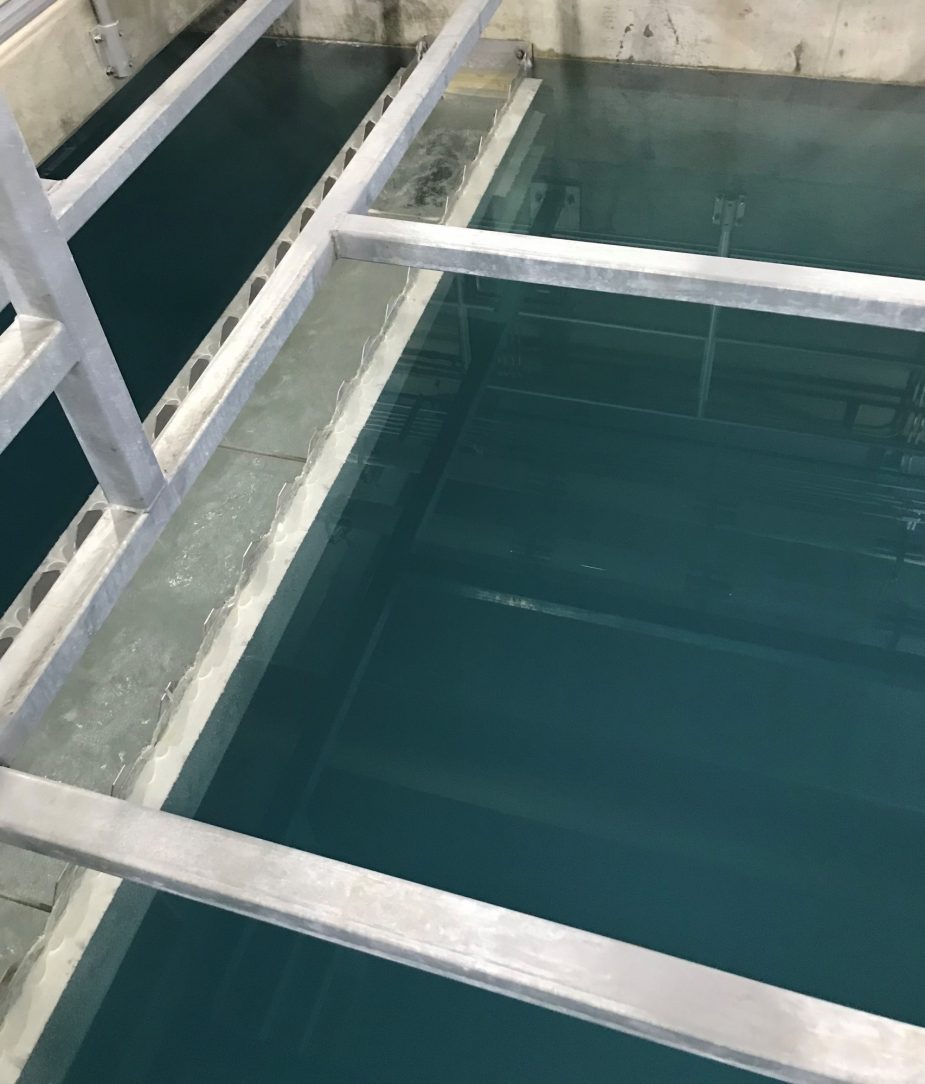

Hot dip galvanizing was specified for this project to provide longevity of the system. Since the water has a pH balance of 8, which is base, there should be minimal corrosion. Structurally the steel will support the railings, plates, and concrete in place. With square tubing being utilized, we were able to coat the internal and external of the steel. Venting and draining holes were discussed before fabrication to ensure premium outcome of the product with minimal runs and drips.

The city of Toledo specified a sustainable system that would last over 100 years. They chose hot dip galvanizing, along with duplex coatings for the structural beams, and stainless steel for steel submersed in water. Collins Park Water Treatment Plant guarantees that consumers are provided with crystal clear water of the highest quality. Testing of the water is performed 24 hours per day 365 days per year. This testing gives our operational personnel timely information, so that adjustments can be made to the treatment process to ensure constant water quality is met.

The plant has a quality control laboratory in which hourly analysis is performed on raw and treated water. The amount of chemicals used in water treatment is comparatively small, so small in fact that the total amount of chemicals needed to properly treat 100 gallons of water would amount to about one teaspoonful, or 15 parts of chemical to one million parts of water. The process of filtering the water is monitored and tested continuously by a highly trained staff of professionals. Monitoring, like the production process, is also a 24 hour a day job.

Details

Award Class

Newly Complete

Award Sectors

Water & Marine

Environment

Industrial/Urban

Location

Toledo, OH United States

Reasons for Galvanizing

Aesthetics, Coating Durability, Corrosion Performance, Ease of Specifying, Initial Cost, Life-Cycle Cost, Prior HDG Experience, Quality of HDG, Sustainability, Turnaround Time

Components Galvanized

Square tubing

I-Beam headers

Plates

Tonnage/Size

Steel: 75

HDG: 25

Team Members

Fabricator

Bill Murry

Thermeq

Other

Jake Kusmer

Mosser Group

Member Galvanizer(s)

AZZ Galvanizing - Hamilton

Thank you! Your vote has been accepted.