Menu • Quick Links • Search

Login

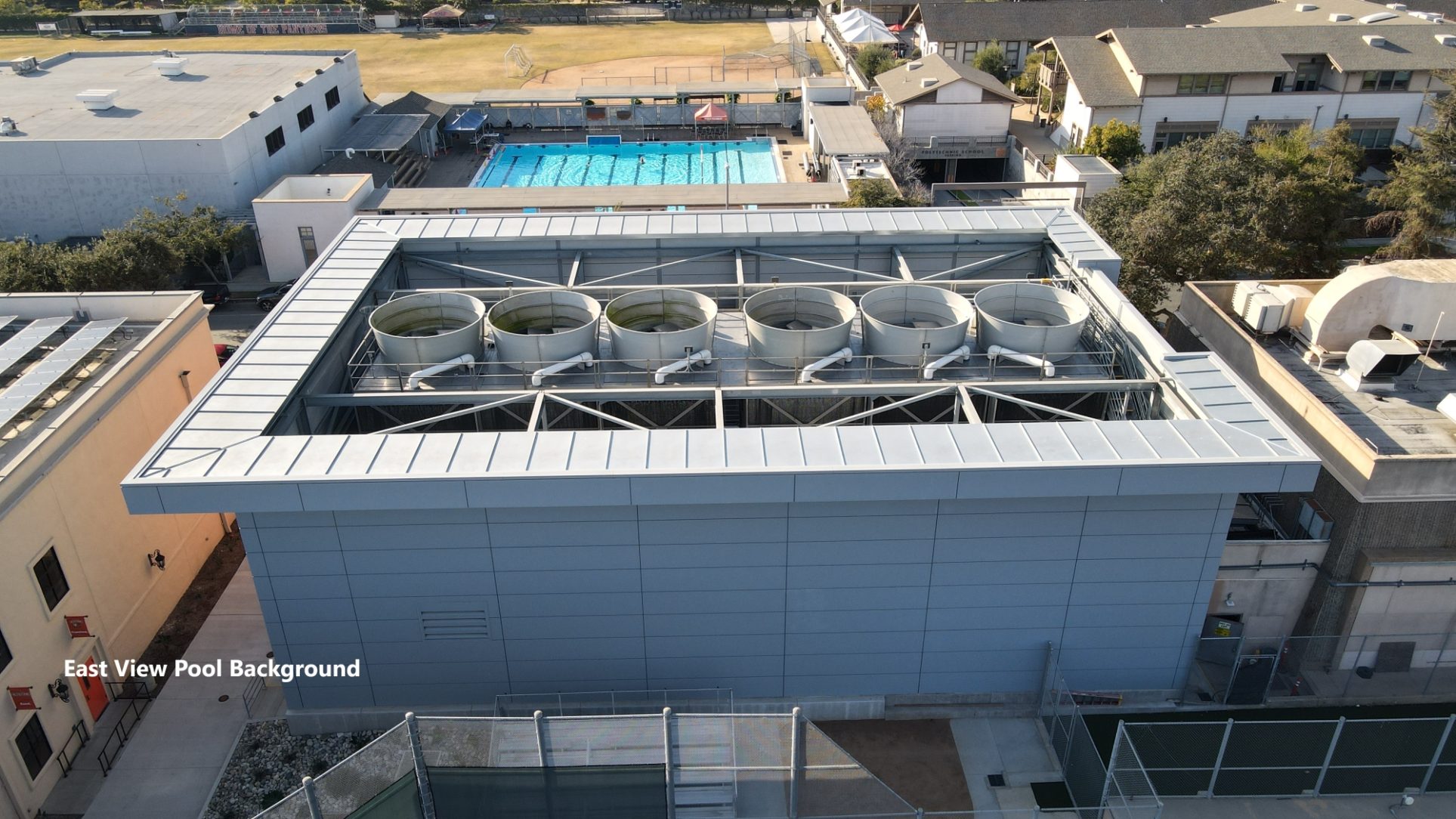

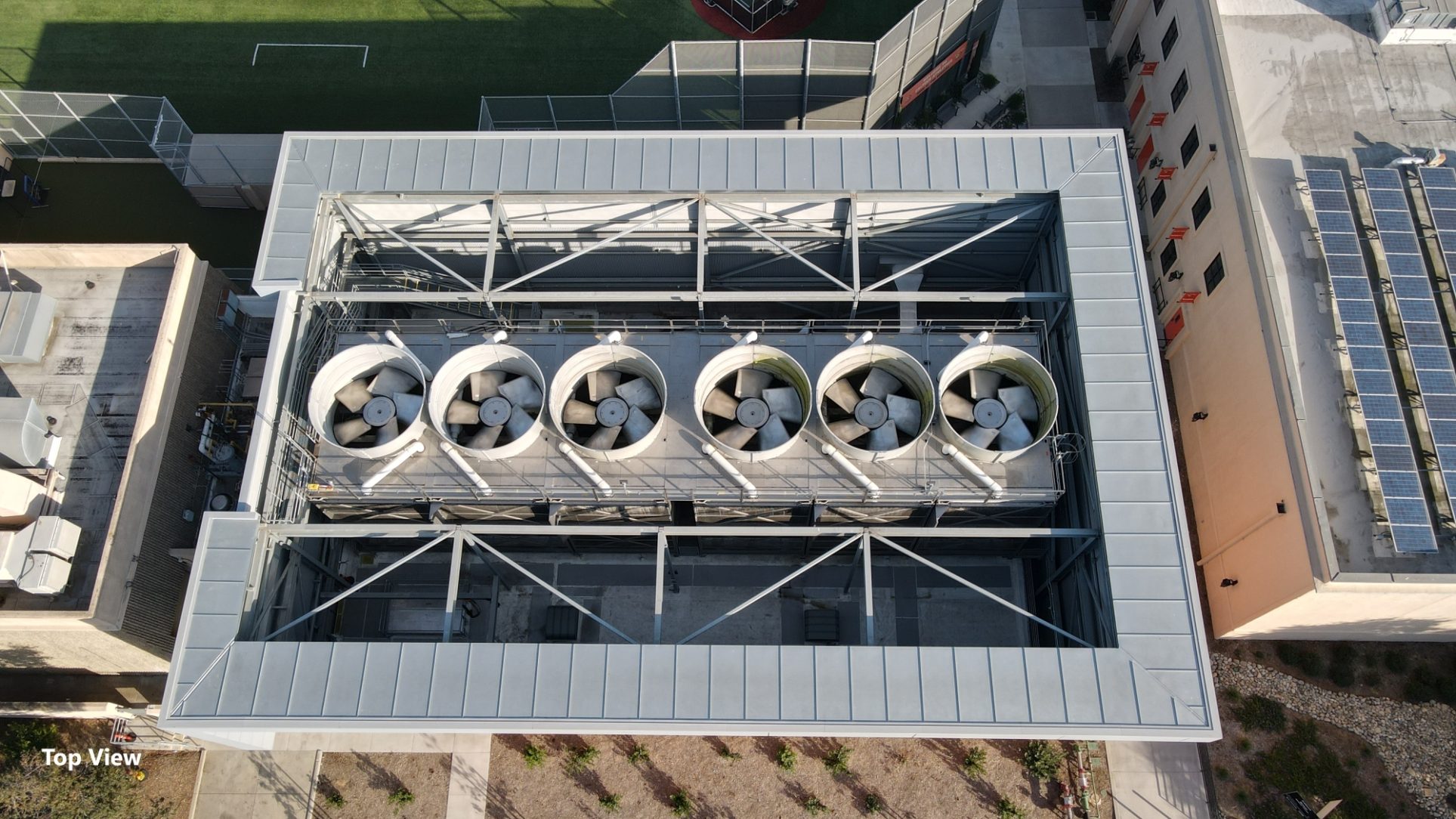

CloseThe newly renovated Central Utility Plant at the Caltech campus is instrumental in maintaining optimal conditions for sensitive research equipment. The $22 million upgrade addressed challenges arising from the aging infrastructure of the previous system (circa 1980), which struggled to adapt to the evolving demands of a cutting-edge research environment. Constructed on Wilson Avenue, the six stainless steel cooling towers utilized hot-dip galvanized steel to replace outdated support framing and components, offering improved structural integrity and reliability.

The six stainless steel cooling towers utilized hot-dip galvanized steel to replace outdated support framing and components, offering improved structural integrity and reliability.

This enhancement was crucial to meet increasing demands for energy efficiency, sustainability, and adaptability to fluctuating weather conditions. The recirculated cooling water, flowing through the towers, serves as a vital coolant for intricate laboratory instruments and high-tech machinery within campus buildings. Efficiently dissipating heat through the towers' evaporation process ensures that sensitive equipment operates within its designated temperature range, safeguarding critical research processes. Additionally, the recirculated cooled water allows HVAC systems to cool classrooms and research facilities.

The strategic choice of hot-dip galvanized steel significantly added value to Caltech's ambitious upgrade project. This material plays a pivotal role in ensuring structural integrity, durability, and long-term resilience in the face of environmental elements and seismic considerations. The hot-dip galvanizing process, immersing steel components in molten zinc, creates a metallurgical bond that adds an extra layer of protection. The resulting zinc coating acts as a sacrificial (anode) layer, shielding the steel (cathode) from corrosive elements. This provides a durable and corrosion-resistant structure, aligning seamlessly with Caltech's commitment to sustainability and longevity in infrastructure investments. The inherent corrosion resistance of hot-dip galvanized steel is particularly crucial in sustaining the longevity of the projects infrastructure and the effectiveness of the cooling system.

In summary, the Caltech campus, nestled in Pasadena's scenic landscape, has undergone a transformative upgrade integrating cutting-edge technology and sustainable practices. From water-cooling towers to noise reduction measures and seismic compliance, Caltech's commitment to innovation extends beyond research to the very infrastructure supporting its academic endeavors.

Details

Award Class

Newly Complete

Award Sectors

Electrical, Utility & Communication

Environment

Suburban

Location

Pasadena, CA United States

Reasons for Galvanizing

Coating Durability, Corrosion Performance, Ease of Specifying, Life-Cycle Cost, Sustainability, Turnaround Time

Components Galvanized

Beam and Tube Steel Columns, Tube Steel Frames, Embeds, Components

Tonnage/Size

Steel: 86

HDG: 86

Team Members

Fabricator

Daniel Nunez

Schroeder Iron

Member Galvanizer(s)

Valmont Coatings - Calwest Galvanizing

Thank you! Your vote has been accepted.