Menu • Quick Links • Search

Login

CloseThe Bigfoot XL motorized utility cart is Taylor-Dunn’s premier utility vehicle, offering both durability and performance in an affordable package. The unit is equipped with a 17hp, 48 volt AC motor, GT drive, rack and pinion steering and all-wheel hydraulic disc brakes with a top speed of 18 mph. The cart seats two adults comfortably and has a large tow capacity rating of five tons, making it the foremost leader in its class.

Taylor-Dunn motorized utility carts have a well-earned reputation of being built to last and the hot-dip galvanizing industry plays an integral part in that by maintaining the structural integrity of this utilitarian vehicle. Hot-dip galvanizing the base steel framework ensures it is adequately protected from corrosion in the varied and sometimes harsh commercial environments where it will be commissioned.

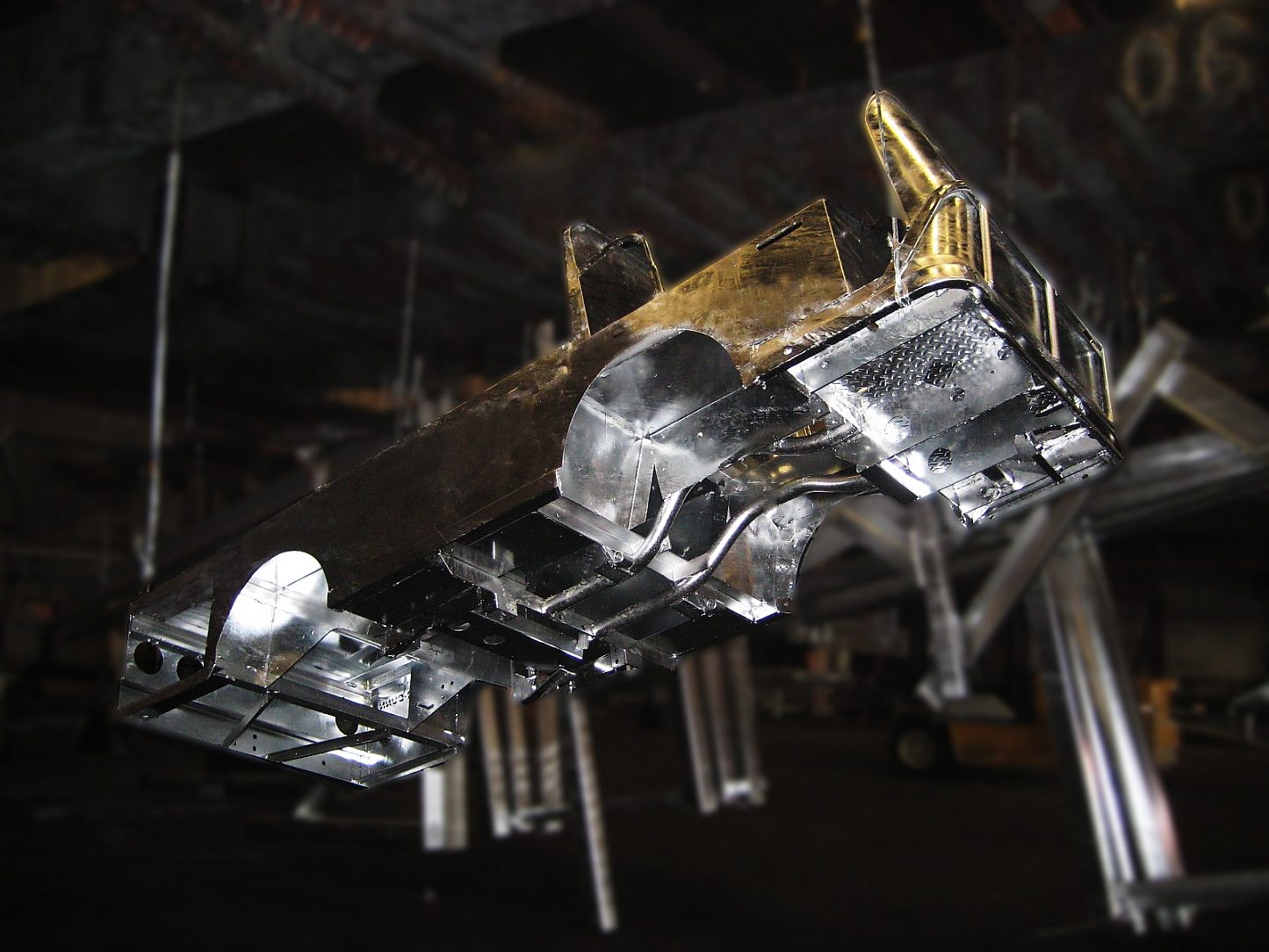

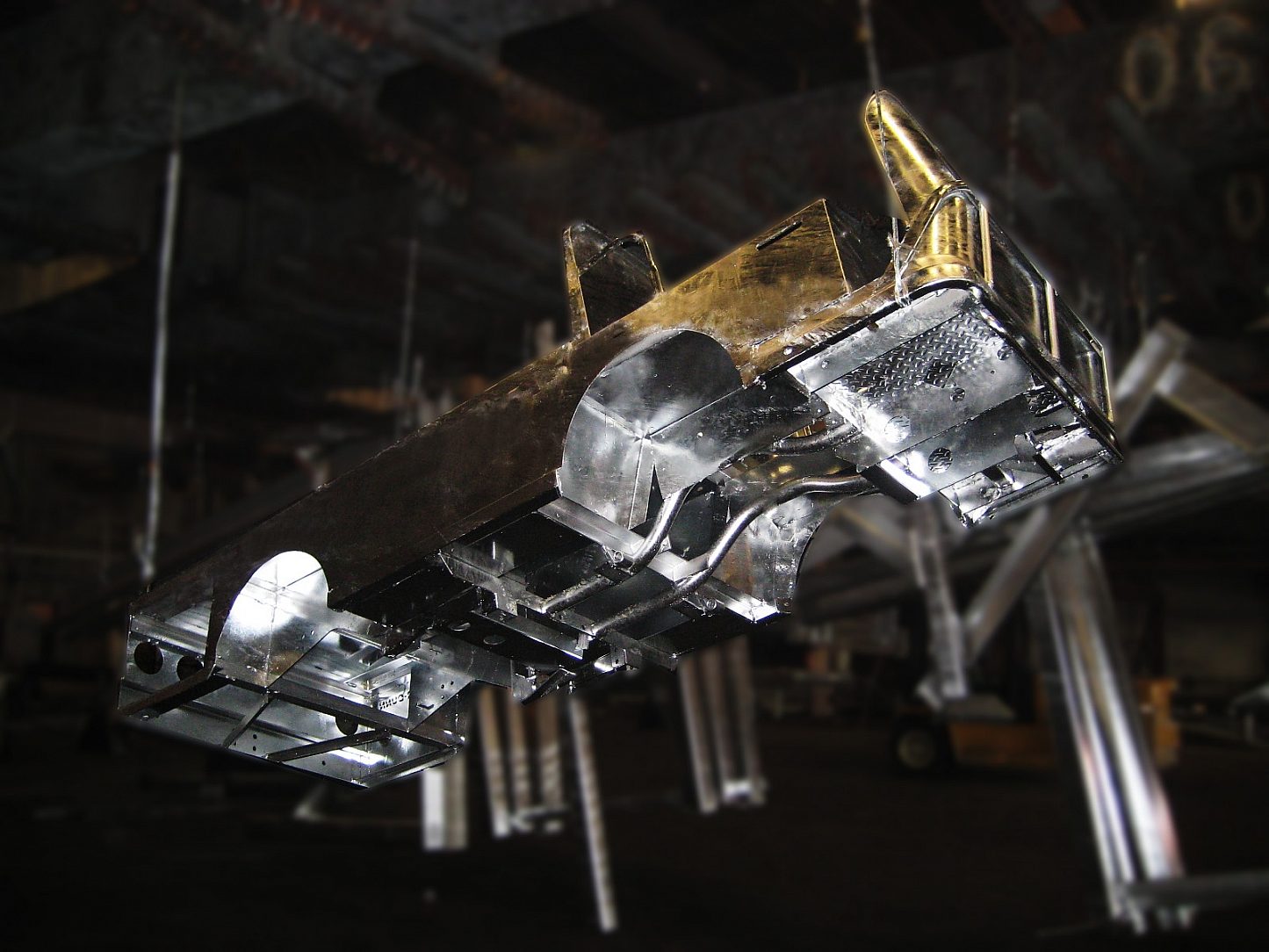

The hot-dip galvanizing of the utility cart frames can be a bit tricky because it requires hanging them at specific angles to help with not only the initial submersion of the material into the molten zinc but also for proper drainage when removing it from the molten zinc.

The hot-dip galvanizing of the utility cart frames can be a bit tricky because it requires hanging them at specific angles to help with not only the initial submersion of the material into the molten zinc but also for proper drainage when removing it from the molten zinc. Occasionally the manufacturer will build custom (Bigfoot XL) units to match an individual customer’s exact specifications. This requires the hot-dip galvanizer to check for any major modifications on the custom frame that would require it to be hung at a different angle (than usual) on the rack, thus providing the customer the best possible hot-dip galvanized product every single dip.

After the utility cart frames are hot-dip galvanized they are weighed, cleaned and inspected before being delivered back to the customer where the zinc’s malleable Eta layer (of the hot-dip galvanized frame) is completely etched to properly prepare the entire galvanized surface for a glossy custom paint finish, therein completing the duplex coating process.

After the Bigfoot XL is fully assembled, it is transferred over to a dealership to be sold. Here in the United States, Yale/Chase is of the main authorized dealer. They market and sell the Bigfoot XL, which are used for numerous heavy-duty applications including airline transportation (baggage & fuel), convention center back lots, warehouses, factories and ports-of-call. The Bigfoot XL offers extraordinary value in that it allows on-site workers to complete their daily transporting tasks in an eco-friendly, efficient and safe manner.

It is truly amazing to sit back and think about how many different industries use and appreciate our unique hot-dip galvanizing process and we take great pride in offering such an important and valuable service, helping to extend the life cycle of steel components.

Taylor-Dunn has been in business since 1949 and has an extensive product line that includes burden carriers, electric trams, stockchasers, tow tractors, personnel carriers, commercial vehicles and their renowned utility carts.

Yale/Chase is known as a solutions partner in Southern California with a vast product lineup that includes forklifts, generators, railcar movers, terminal tractors and utility vehicles.

Details

Award Class

Newly Complete

Award Sectors

Original Equipment Manufacturing

Environment

Temperate Marine

Location

City of Industry, CA United States

Reasons for Galvanizing

Corrosion Performance, Life-Cycle Cost, Prior HDG Experience

Components Galvanized

Steel Utility Cart Frame (4’ x 2’ x 11’)

Tonnage/Size

Steel: 1

HDG: 1

Team Members

Others

Taylor-Dunn

Yale/Chase

Member Galvanizer(s)

Valmont Coatings - Calwest Galvanizing

Thank you! Your vote has been accepted.