Menu • Quick Links • Search

Login

CloseBack in the 1960s, the San Francisco Bay Area created a large railway the connected Oakland, San Francisco and the Hayward areas. This project was a very large project and took many years to construct, it is known to the local people as "BART", Bay Area Rapid Transit. Once the rail line was completed in the late 1960's it saved the local people time when commuting from place to place.

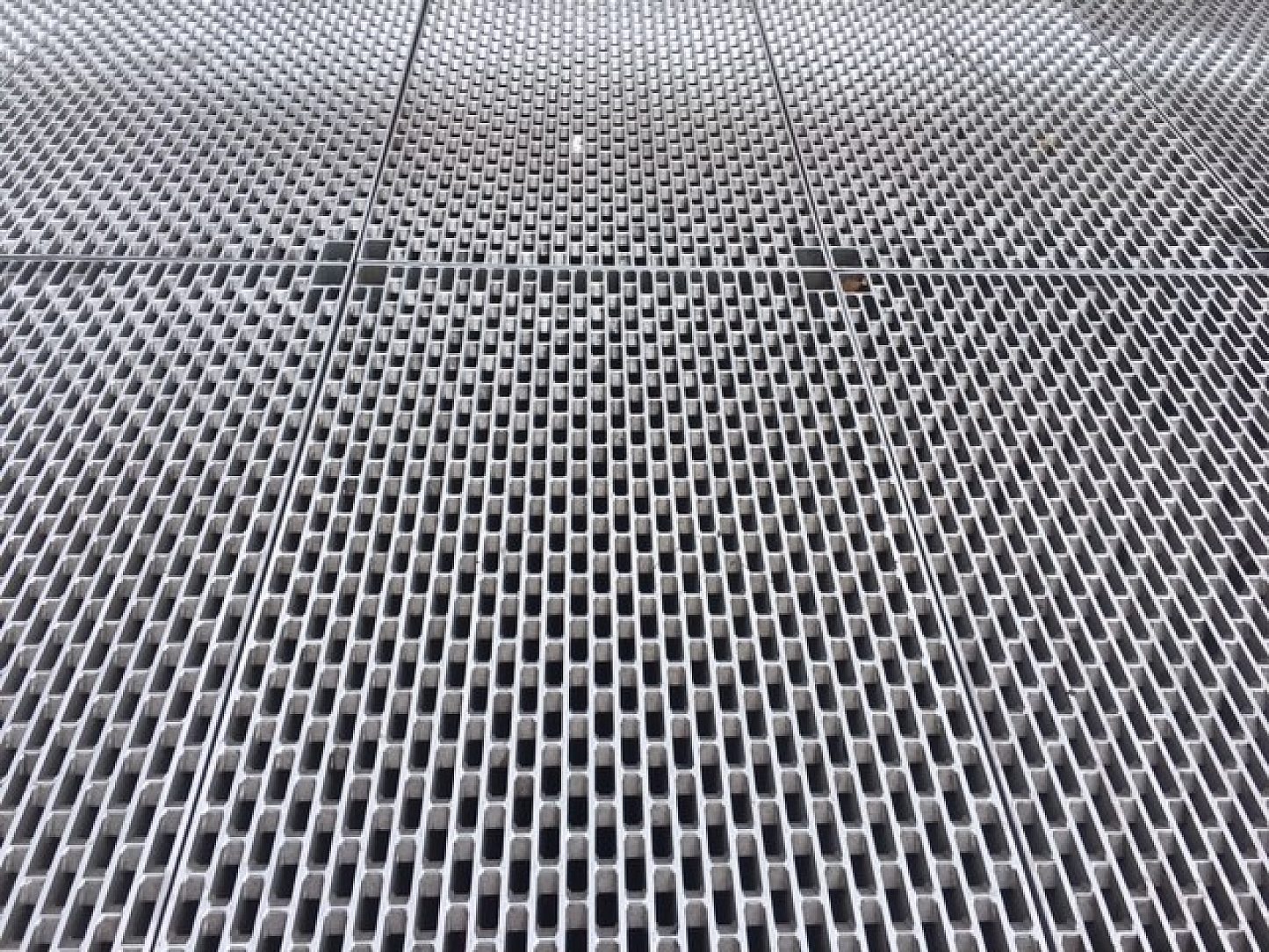

Each grate, weighing close to two thousand pounds, is custom made out of a thick plate.

A large factor why BART is important to the people of the bay area is that when it was constructed, the line has tunnels that go through mountains, under water, and under the city streets. One of the main stops on the BART rail is the 24th Street Mission Station. This stop is downtown San Francisco surrounded by shops, high rise apartments, and many tourist walking, viewing the city of San Francisco. The BART line actually runs under Mission Street and when sitting on Mission Street along with the traffic you can occasionally hear the BART line pass under the city. The reason you can hear the transit line is because on the streets are large grates that buses and cars constantly drive over, even people walking the streets easily walk over the large steel grates. These grates allow transit workers easy access to the line for maintenance and safety purposes.

The original grates were made out of steel with no special or particular coating on them. After many years of constant traffic and pressure the original grates had to be replaced. The new replacement steel grates are not a standard welded bar grating, with flat bars welded together. Each grate, weighing close to two thousand pounds, is custom made out of thick plate and have angles welded into each square section to help support the heavy weight of buses, semi-trucks, and cars as they get a constant force of heavy weight put on them twenty four hours a day seven days a week.

The San Francisco Bay Area Transit team made a great decision not only designing a great looking product they also made the decision to have them all hot dipped galvanized. For this project, in total, there were one hundred and thirty one grates, close to two hundred and fifty thousand pounds of steel, which were replaced with the new and updated galvanized grates. The HDG chemical bond with the carbon steel will save thousands of tax paying dollars due to not having to repair or maintenance the product. The HDG will also protect against the harsh salty sea air of San Francisco. Not only will the HDG protect the product for many years to come, it also gives the streets of San Francisco a bit color. Instead of a brown and rusty orange color in the middle of the road is a colorful gray that sits nice with the black asphalt surrounding it.

Details

Year Galvanized

2015

Award Class

Newly Complete

Award Sectors

Transportation

Environment

Industrial/Urban

Location

San Francisco, CA United States

Reasons for Galvanizing

Aesthetics, Coating Durability, Corrosion Performance, Initial Cost, Prior HDG Experience, Quality of HDG, Turnaround Time

Components Galvanized

All the components of the project are galvanized.

Tonnage/Size

Steel: 125

HDG: 125

Team Members

Owner

Unknown

Bay Area Rapid Transit

Member Galvanizer(s)

AZZ Galvanizing - Reno

Thank you! Your vote has been accepted.