Menu • Quick Links • Search

Login

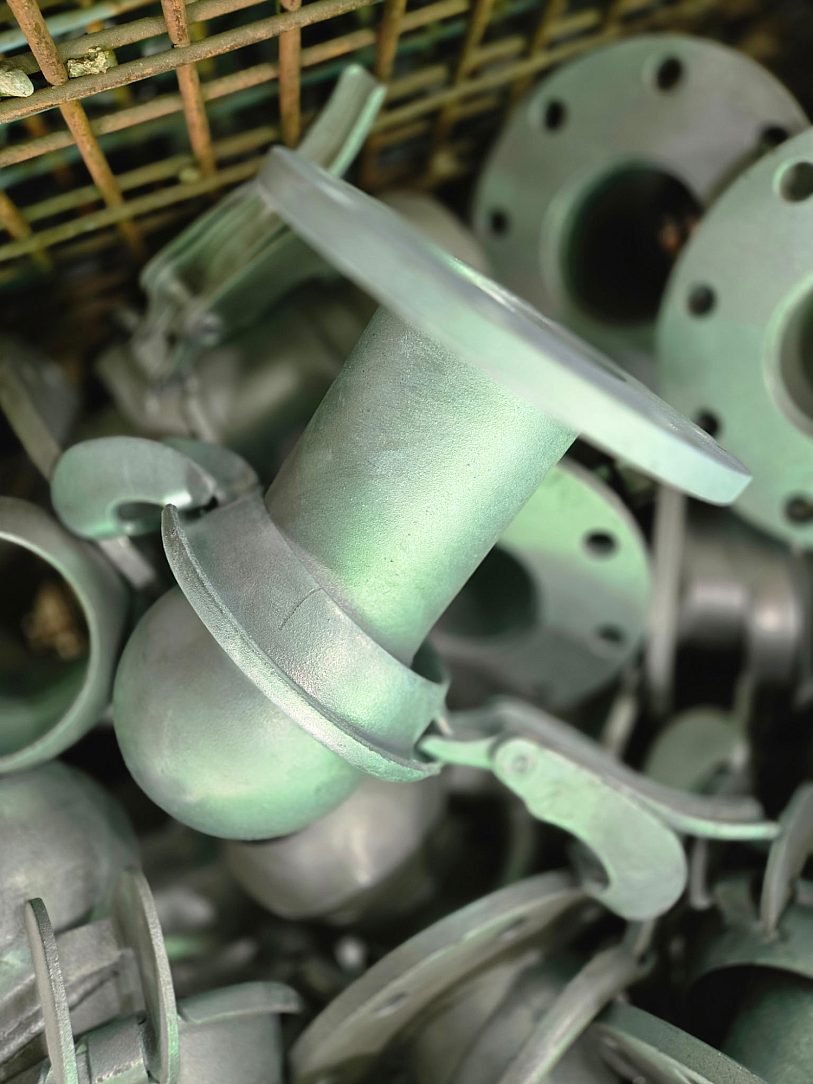

CloseFor decades, the portable piping industry has supported temporary and mobile operations by supplying specialized pipe and fittings designed for rapid deployment and repeated use. Across the industry, hot-dip galvanizing has become the preferred corrosion protection system, recognized for its proven performance in demanding, real-world service conditions. Portable piping systems face unique durability challenges due to frequent installation, disassembly, transportation, and storage across multiple job sites and environments. These repeated cycles expose steel components to moisture, abrasion, debris, and corrosive materials that can significantly shorten service life if not properly protected. Hot-dip galvanizing delivers a robust, long-term solution by forming a metallurgically bonded zinc coating that shields steel from corrosion, impact, and handling damage.

Portable piping systems are designed to enable rapid connection and disassembly, allowing piping assemblies to be deployed, removed, and redeployed efficiently across multiple job sites. This flexibility is fundamental to the industry, where temporary piping solutions must adapt quickly to changing project demands and locations. The durability provided by hot-dip galvanizing offers exceptional resistance to impact, handling damage, and abrasion-performance attributes that are especially critical for portable piping products that are routinely moved, stacked, and reconfigured on active jobsites. In these environments, coating damage is difficult to avoid; however, even when minor surface wear occurs, the surrounding zinc continues to provide sacrificial protection, preventing the initiation and spread of corrosion. A key advantage of hot-dip galvanizing for portable piping systems is the complete and uniform coating coverage achieved through full immersion in molten zinc. This process protects both exterior and interior surfaces of the piping, including seams, joints, and other areas that are difficult or impossible to coat effectively using alternative methods. Interior corrosion is a common failure mechanism in piping systems that convey sediment-laden or corrosive fluids. By fully coating internal surfaces, hot-dip galvanizing significantly reduces the risk of corrosion-related blockages, leaks, and structural degradation-ensuring consistent flow performance, structural integrity, and long-term system reliability throughout repeated service cycles

Details

Award Class

Newly Complete

Award Sectors

Original Equipment Manufacturing

Environment

Suburban

Location

North America, PA United States

Reasons for Galvanizing

Coating Durability, Corrosion Performance, Life-Cycle Cost

Components Galvanized

Pipes, pipe fasteners, hose fittings, pipe racks/ storage.

Tonnage/Size

Steel: 1

HDG: 1

Team Members

Fabricator

Wolf Creek Portable Piping Products

Member Galvanizer(s)

V&S Korns Galvanizing

Thank you! Your vote has been accepted.