Menu • Quick Links • Search

Login

CloseBunkhouse specialty trailers are a great option for temporary or emergency housing when traditional lodging isn't available. They are a critical aspect of post-disaster recovery efforts for individuals and families. Bunkhouses offer a level of comfort and mobility to victims of hurricanes, tornados, wildfires, floods, and other natural disasters.

These trailers frequently operate in rugged, post-disaster locales and are often exposed to various environmental conditions, including rain, snow, road salt, and tropical humidity. Such conditions can lead to the corrosion of metal components, which can quickly compromise the structural integrity and appearance of the trailer.

By galvanizing the trailers’ vital metal components, JAG ensures their products remain in good condition for an extended period, reducing the need for frequent repairs or replacements.

JAG Mobile Solutions Inc., located in Howe, Indiana wanted to offer corrosion protection for their custom-built bunkhouse product, an impressive unit equipped with 12 private bedrooms, HVAC and electrical capabilities. A variety of floor plans are available including models with shower and restroom facilities. Separate mobile restroom and portable shower trailers are also available.

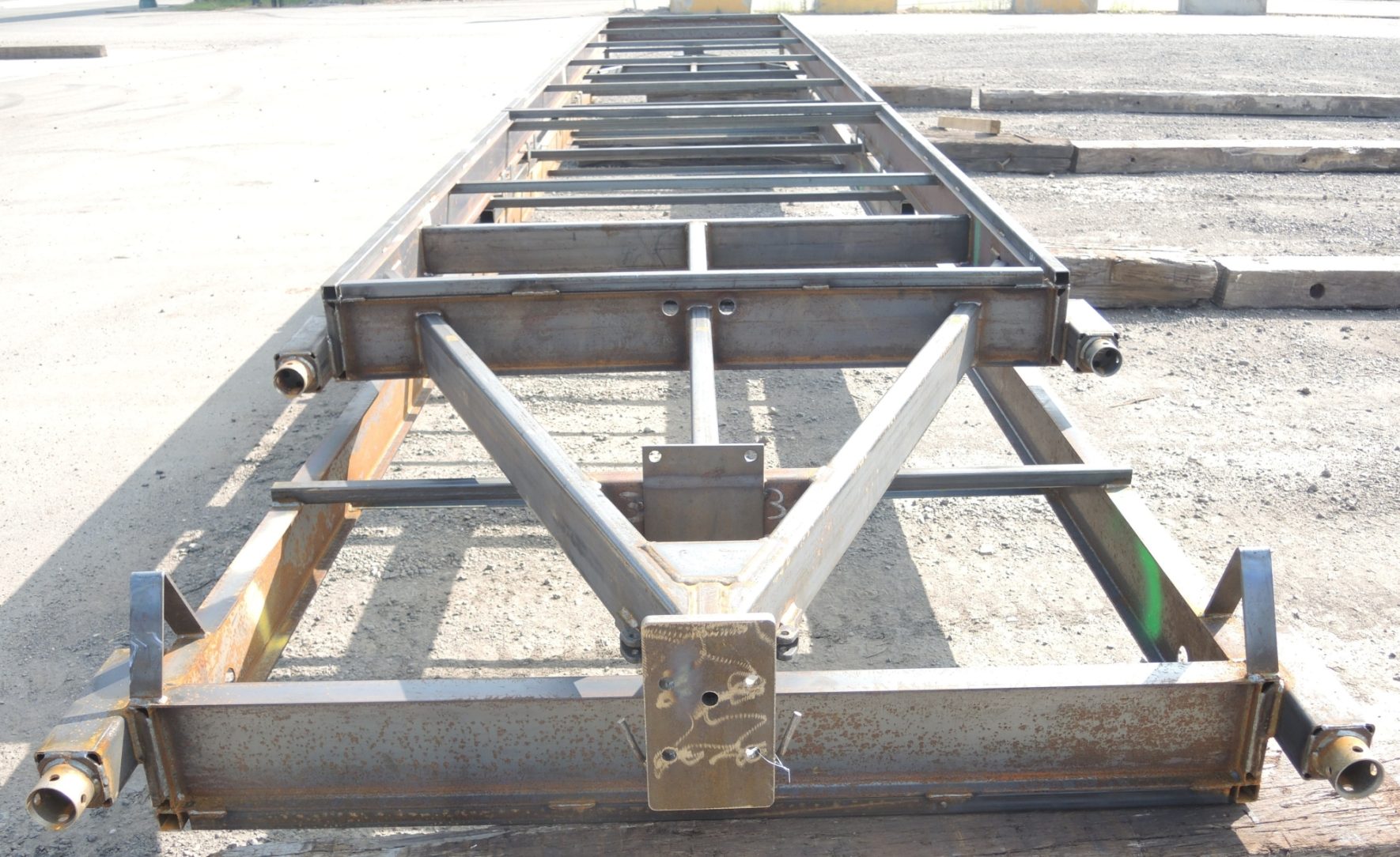

JAG, a quality-focused company with a demonstrated appreciation for the advantages provided by hot-dip galvanizing, made the choice to have their chassis, tongues, service area boxes, and waste tanks hot-dip galvanized over other coating options. By galvanizing the trailers’ vital metal components, JAG ensures their products remain in good condition for an extended period, reducing the need for frequent repairs or replacements.

Additionally, thanks to regular communication with the galvanizer early in the design phase, JAG was able to explore design options that maximize the benefits of galvanizing while ensuring that the final product met functional and aesthetic requirements. Details such as properly sized vent and drain holes may seem trivial, but their implementation is critical to the long-term success of a project.

It should also be noted that hot-dip galvanizing is a versatile process that can be applied to a wide range of shapes and sizes. As the trailer’s chassis design includes hollow sections, galvanizing provides the unique advantage of equal, internal protections again undetectable corrosion from perpetuating inside the hollow members.

Moving forward, the specialty trailer market has been experiencing growth and innovation in recent years due to increased demand for both post-disaster recovery and family-friendly RV options. Manufacturers have been introducing new models with improved features and designs to cater to a broader customer base. This unique bunkhouse application has the potential to favorably impact the hot-dip galvanizing market, and sharing the success of galvanizing this product has opened doors to provide the HDG advantage for several other similar applications experiencing corrosion concerns.

Details

Award Class

Newly Complete

Award Sectors

Original Equipment Manufacturing

Environment

Tropical Marine

Location

Western, FL United States

Reasons for Galvanizing

Coating Durability, Corrosion Performance, Initial Cost, Life-Cycle Cost, Prior HDG Experience, Quality of HDG, Sustainability, Turnaround Time

Components Galvanized

Chassis

Tonnage/Size

Steel: 100

HDG: 100

Team Members

Fabricator

Somerville Industries

Owner

JAG Mobile Solutions

Member Galvanizer(s)

AZZ Galvanizing - Canton

Thank you! Your vote has been accepted.