Menu • Quick Links • Search

Login

CloseThe Tulsa Zoo has a successful history of exhibiting and caring for Asian elephants. Driven by their commitment to the species and the individual animals in their care, they developed a plan for expansion and improvements to support a larger, multi-generational Asian elephant herd. Their vision included indoor and outdoor spaces with maximum flexibility for herd management and care around the clock.

Ground was broken on the new Oxley Family Elephant Experience and Elephant Preserve on June 22, 2022. It will be one of the largest facilities of its kind in North America and allow Tulsa Zoo to provide world-class care for elephants at all stages of life.

"Hot-dip galvanizing is the optimum option for these highly corrosive zoo applications that expose the steel to the outdoor elements along with the animals."

The new state-of-the-art elephant barn will be more than 36,000 square feet and will include the addition of natural substrate flooring, which is ideal for foot care, as well as a rain control system, wet stalls, and a full kitchen, which will give keepers and staff greater capabilities while preparing meals for the herd. Combined with the acreage, the new preserve will be a tenfold improvement in terms of its size. Additionally, the zoo will be adding 10 acres for the elephants to free roam. The facility will be completed in December 2023, and the project cost is around $32.8 million, mostly coming from donations.

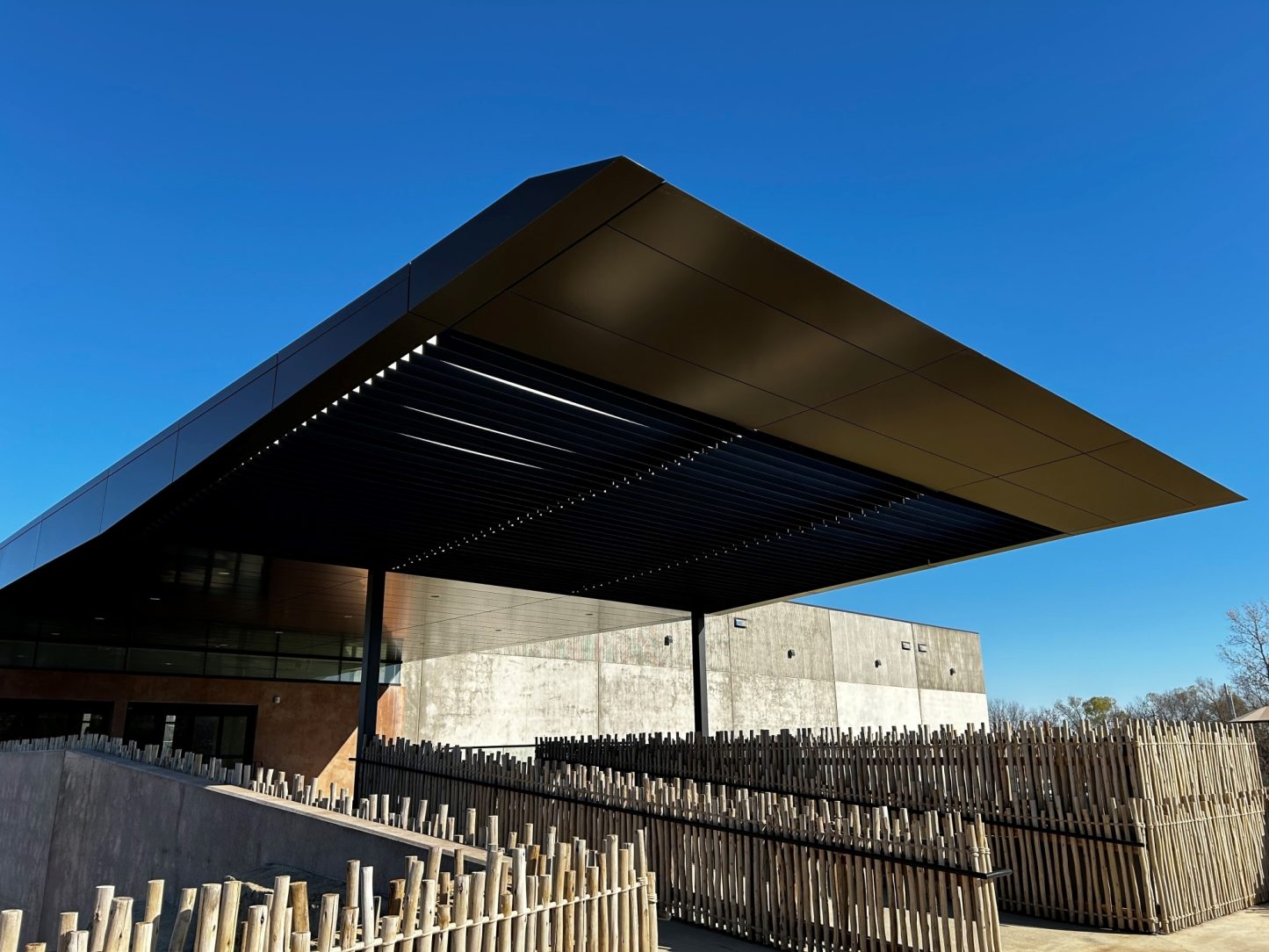

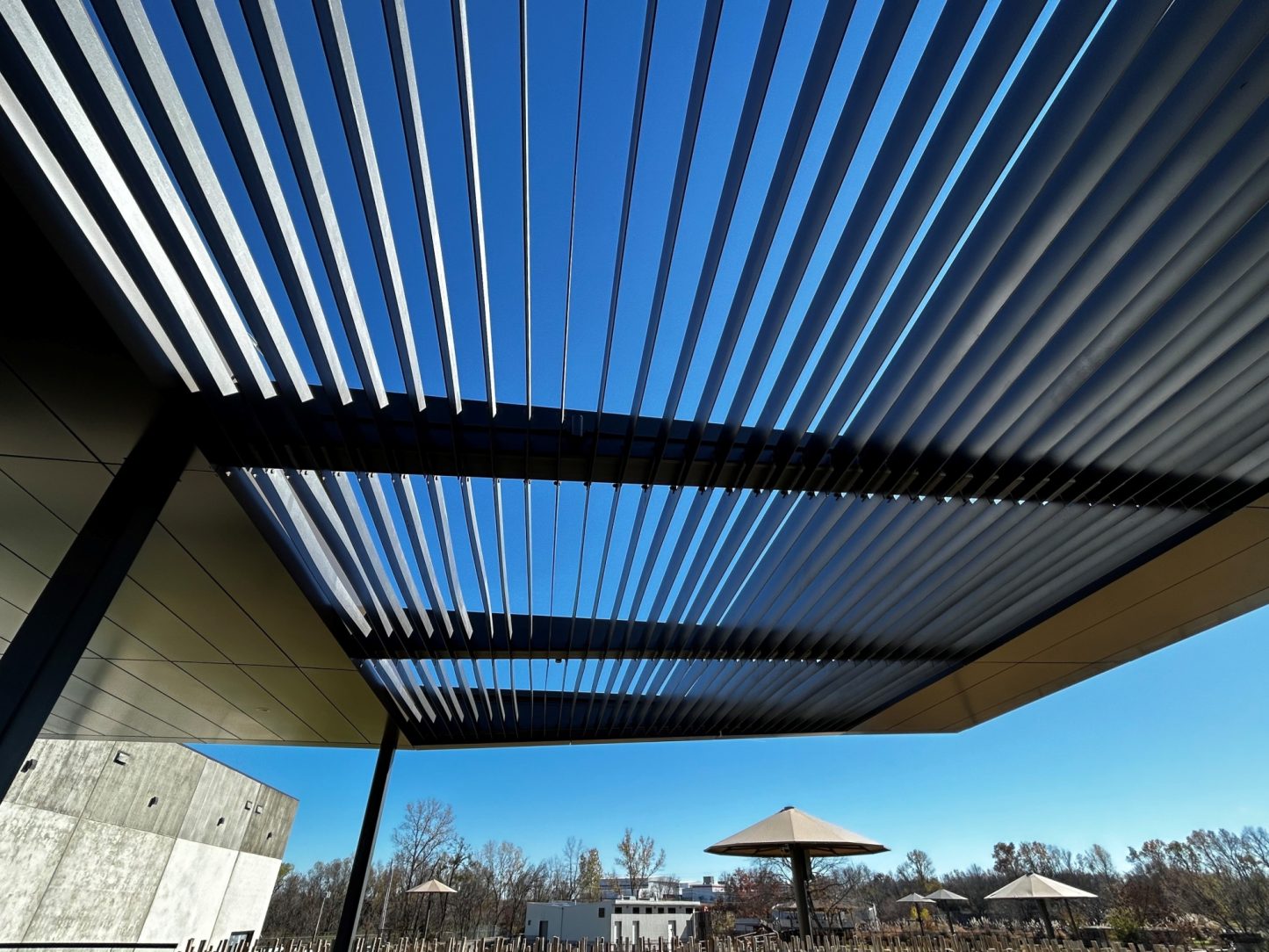

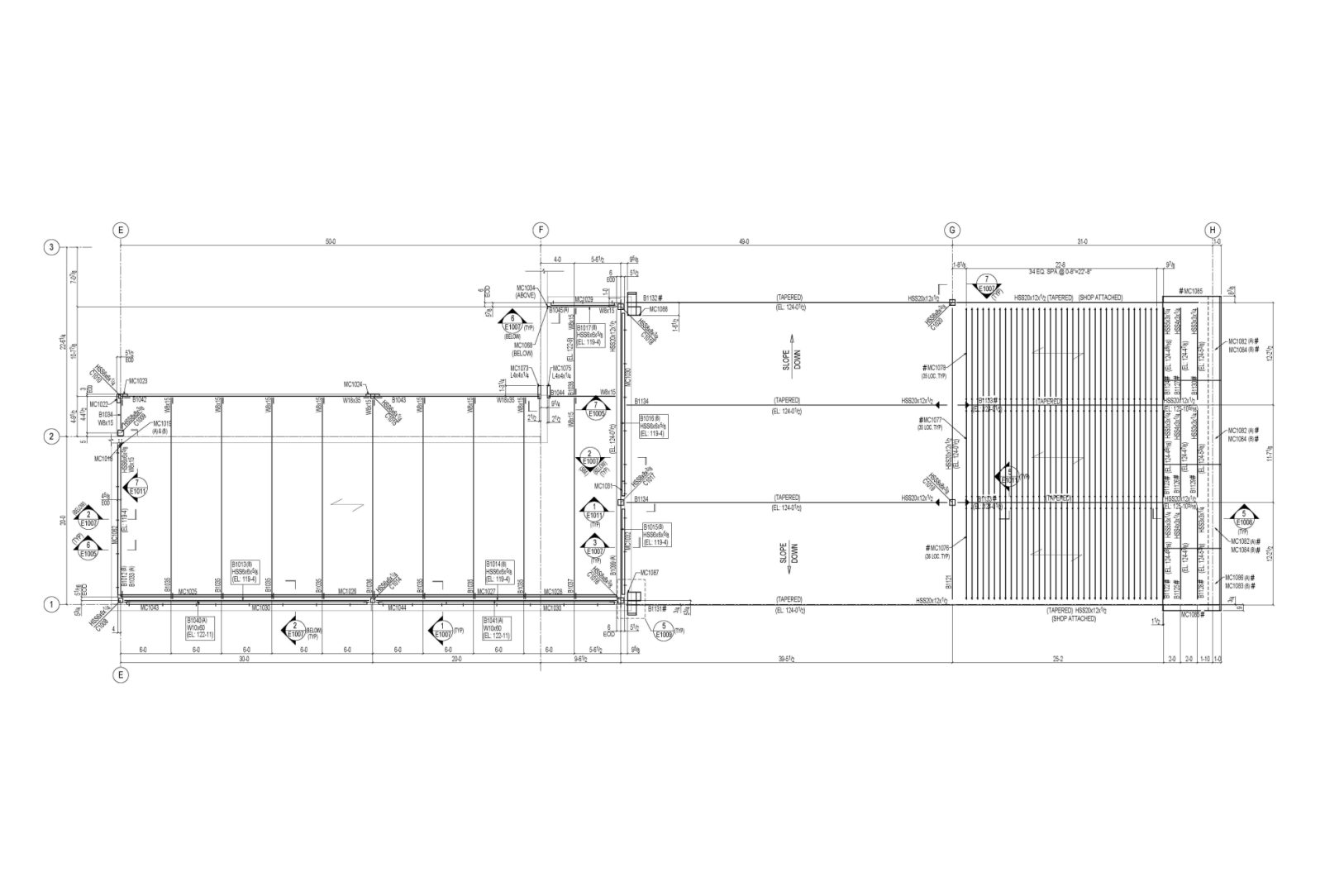

Notably, the canopy for the public entryway to the enclosure was specified to be hot-dip galvanized. Due to its exposure to the elements, the volatile climate of central Oklahoma, and the harshness of being part of a wild animal enclosure; the architects and engineers on this project elected to protect the canopy of the exhibit, along with some of the more exposed structural components with zinc.

The benefits of galvanizing is a perfect marriage to building long-lasting meaningful animal enclosures. Hot-dip galvanizing is the optimum option for these highly corrosive zoo applications that expose the steel to the outdoor elements along with the animals and their waste products. Any zoos not galvanizing all exposed steel structures are well behind the curve. It will prove to be essential to its life span and set an example to the zoological world that we look forward to becoming the standard choice for preserving that which preserves.

Since the canopy is not only visible from outside the exhibit but acts as a welcoming arm to usher guests to the entrance, the design was at the forefront of this piece. Presenting with both modern design cues and the rigid strength of an elephant, the duplex coated canopy design is more than just a covering but a first impression that signals a safe and quality experience. A sophisticated black powder-coat was added on top of the zinc to complete the sharp look of the canopy and further add to the longevity of both coatings (up to 1.5 – 2x) as well as the steel. As a result, this canopy has the longest possible lifespan proving to be a worthy investment for all parties, elephants included.

The integral decision to construct with preservation in mind was an essential piece to honoring the special purpose of the entire exhibit, as well as the many donations that made this possible. Like galvanized steel and the elephants themselves, we know this preservation will last and be remembered.

Details

Award Class

Newly Complete

Award Sectors

Recreation & Entertainment

Environment

Industrial/Urban

Location

Tulsa, OK United States

Reasons for Galvanizing

Aesthetics, Coating Durability, Corrosion Performance, Ease of Specifying, Life-Cycle Cost, Prior HDG Experience, Quality of HDG, Sustainability

Components Galvanized

Fabrication, Plate, Angle, Rectangular Tube

Tonnage/Size

Steel: 4

Team Members

Fabricator

Ryan Cleary

Bennet Steel

Architect

Justin Sack

Selser Schafer

Engineer

360 Engineering

Other

Tulsa Zoo

Member Galvanizer(s)

AZZ Galvanizing - Tulsa

Thank you! Your vote has been accepted.