Menu • Quick Links • Search

Login

Close

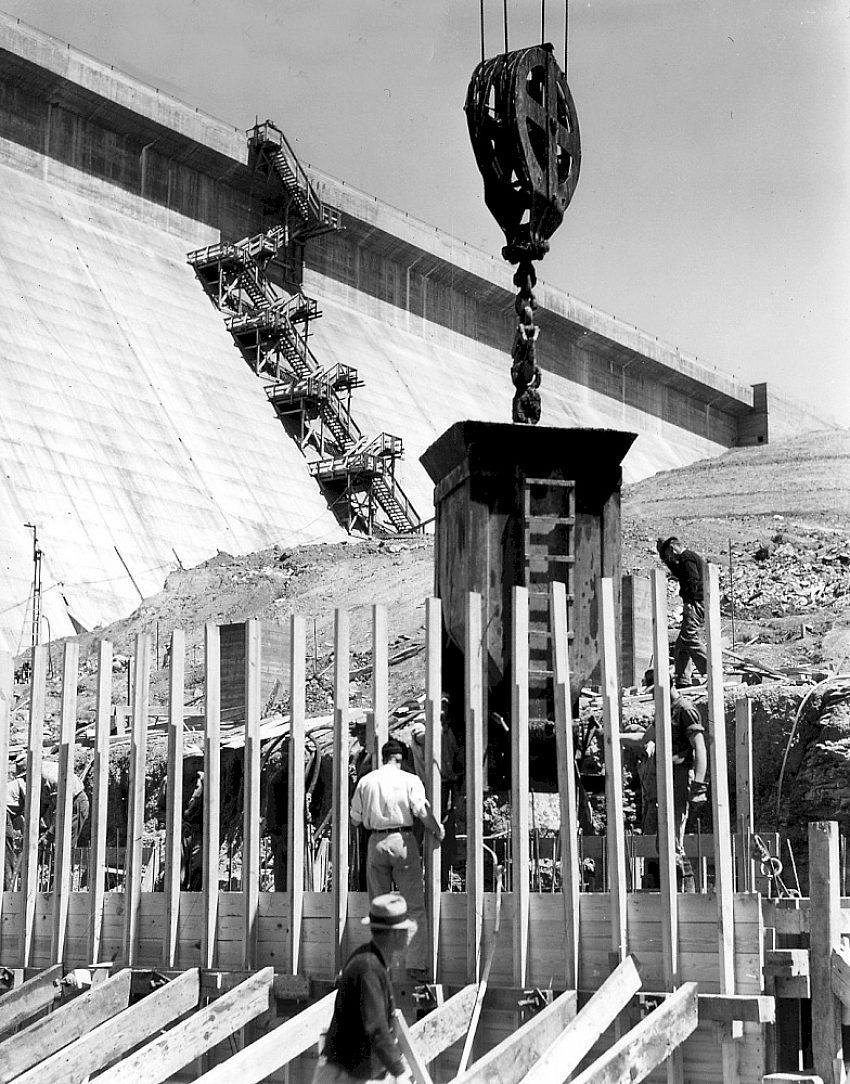

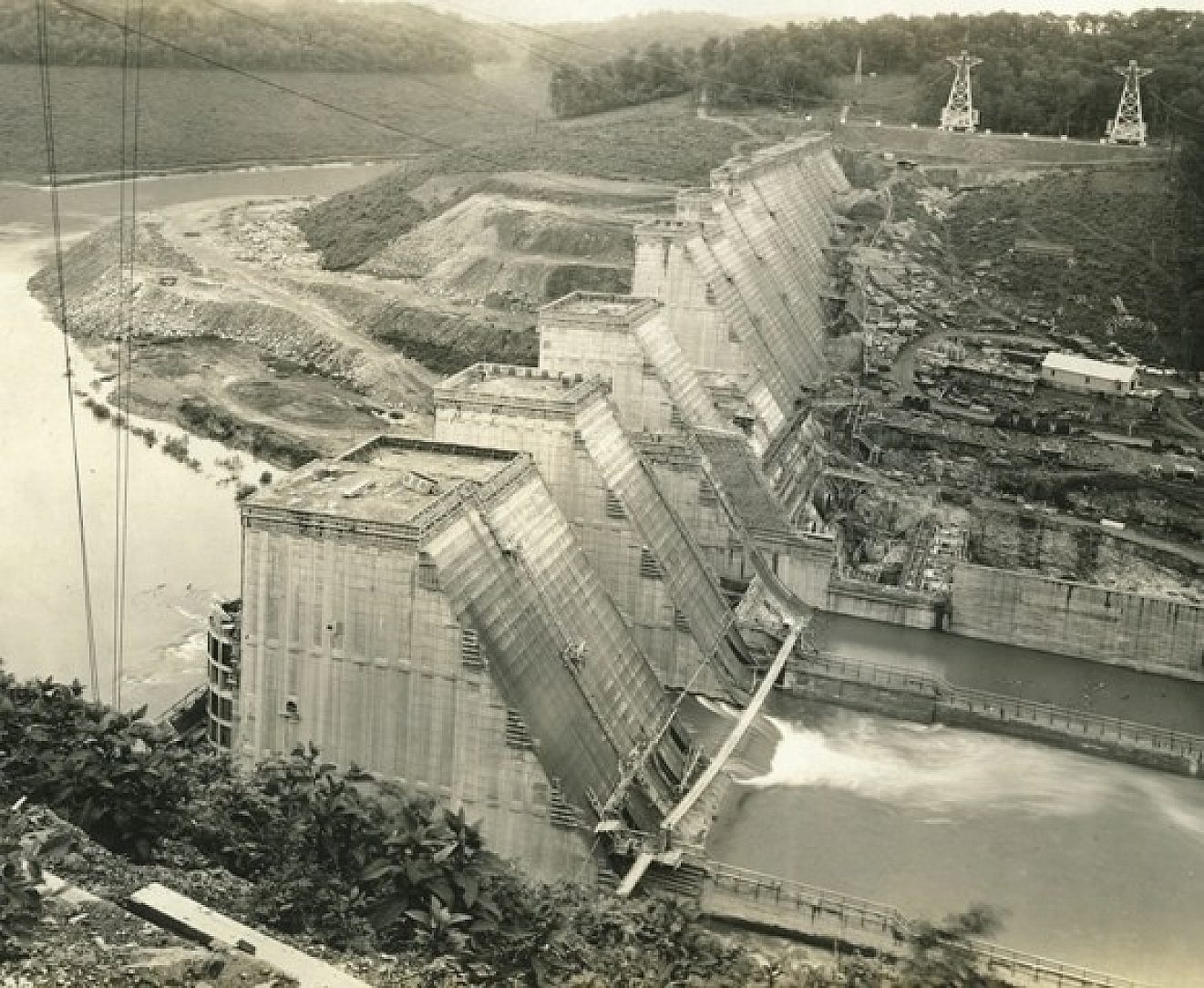

In 1933, as FDR and the United States struggled with the Great Depression, the Tennessee Valley Authority was formed. The TVA was tasked with providing the unserved Appalachian Mountains region with electricity and to provide jobs to the many unemployed people of the area. Immediately the Norris Dam project was started. Three years later, in 1936, the first TVA hydroelectric dam and power generation site was completed in Norris, Tennessee.

The Norris Dam, dual generating units and Substation handles over 100,000 net megawatts of electricity. Galvanized steel was chosen as the preferred material for the substation. TVAs choice of hot-dip galvanized steel has proven to be the right decision.

The historic record of the TVA states, "Switchyard structural steel members are galvanized and bolted together. They were shipped to the job unassembled, with all members punched (galvanized) and ready for assembly. The laced columns and beams were assembled into convenient units for moving into final position and handled into place by cableway. Erection of the structural steel was done by regular job forces.

The substation sits at the base of the dam. It is subjected to the harsh Tennessee mountains winters, Smokey Mountain fog and mist and to the constant moisture from the dams overflow and spillway. It is also just below, and in full view, of the Norris Dam Visitors Center where tens of thousands of visitors view the area every year.

In 1986, the 50th anniversary of construction, the American Galvanizers Association was asked to inspect the structure and offer suggestions for maintenance. Upon inspection it was determined that the steel still had an average of 2.1 mils of zinc remaining on the surface. The steel was completely free of rust or alloy layer staining. Given those facts, no maintenance was recommended.

In 2015, in anticipation of the 80th anniversary of construction, it was again inspected. Due to operational restrictions and beefed up security at the site, no readings could be taken. Close observation does show that there is still no rust or staining even after 80 years of service.

The grandchildren and great grandchildren of the designers and builders of the Norris Dam substation have seen Hot Dip galvanizing provide corrosion free life for 80 years. This lifetime of service is unmatched to this day.

The substation can be viewed from the visitors center six days a week. The center is manned by TVA retirees who are pleased to discuss the 80 year history of the Dam. Stop by and see the lifetime of corrosion free service hot dip galvanizing has provided.

The performance of galvanizing has far exceeded the performance expected when originally specified.

Coating Thickness

| Desc | Read. 1 | Read. 2 | Read. 3 | Read. 4 | Read. 5 | Avg. |

|---|---|---|---|---|---|---|

| Structure | 2.10 | 2.10 | 2.10 | 2.10 | 2.10 | 2.10 |

| Structure | 2.10 | 2.10 | 2.10 | 2.10 | 2.10 | 2.10 |

| Structure | 2.10 | 2.10 | 2.10 | 2.10 | 2.10 | 2.10 |

Details

Year Galvanized

1936

Award Class

Lifetime Achievement

Award Sectors

Lifetime Achievement

Environment

Rural

Location

Norris, TN United States

Reasons for Galvanizing

Coating Durability, Corrosion Performance, Life-Cycle Cost, Quality of HDG, Sustainability

Components Galvanized

Structural Steel, Connections, Bracketry

Tonnage/Size

Steel: 150

HDG: 150

Team Members

Owner

Patricia Bernard Ezzell, Historian

Tennessee Valley Authority

Engineer

Tennessee Valley Authority

Fabricators

Bethlehem Steel, Bethlehem, PA

Lehigh Structural Steel Co., New York, NY

Member Galvanizer(s)

AZZ Galvanizing - Canton

Thank you! Your vote has been accepted.