Menu • Quick Links • Search

Login

CloseSince it’s construction a few decades ago the parking structure at Montreal International Airport has seen ever worsening deterioration. The core problem has been corrosion of the reinforcing bar by water infiltration. This combined with the need to make room for terminal expansion and the inclusion of a new rapid transit station led to the decision to replace and relocate the parking structure. With 2019 passenger traffic exceeding 20 million and growing faster than any other airport in North America, any new construction must be durable, sustainable and rapidly executable.

Hot-dip galvanizing's contribution to the long term durability of this structure is self evident.

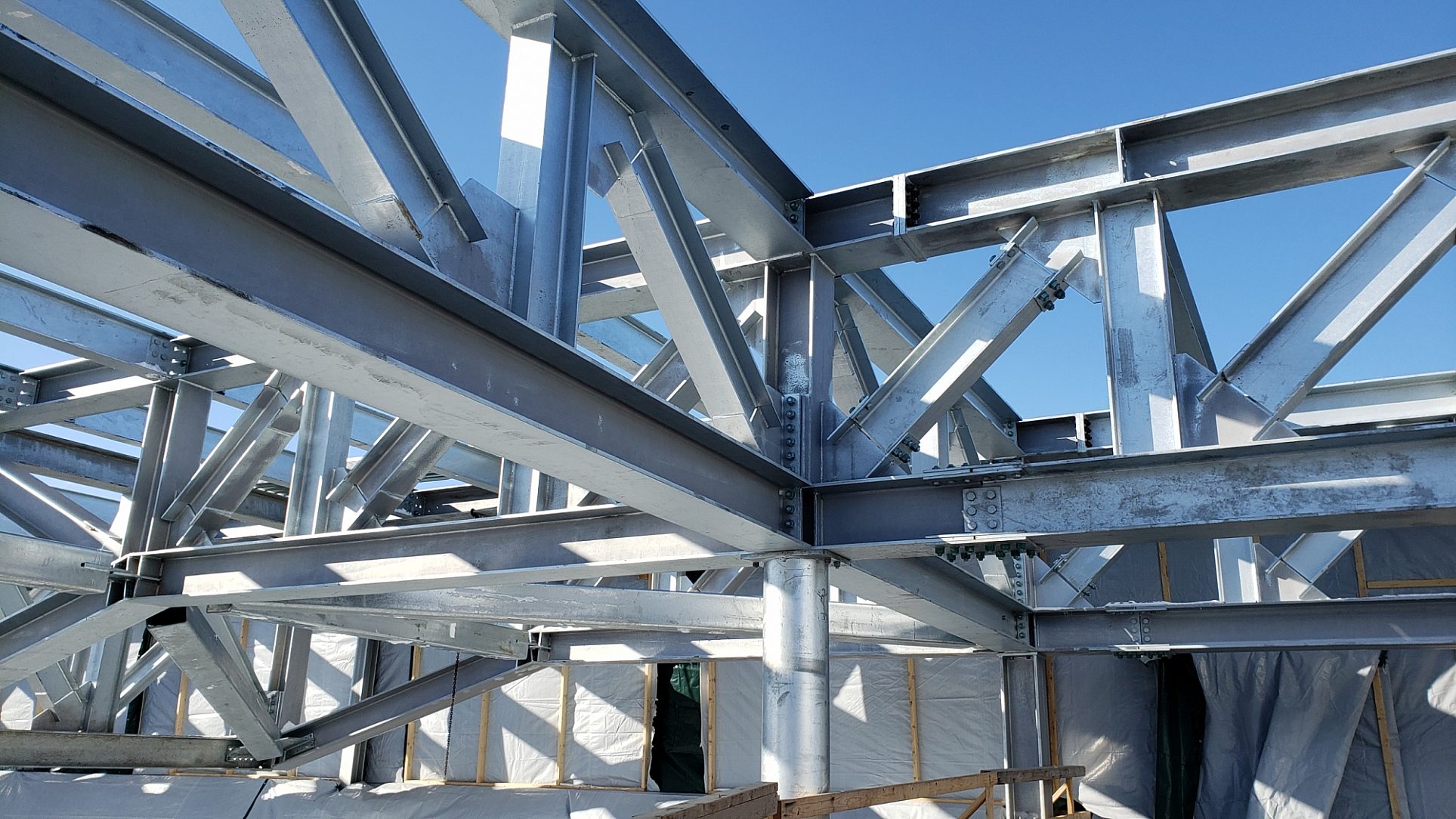

The new parking structure will offer 14,000 spaces to the ever-growing traveler population of the airport. Unlike the previous structure this new concrete structure will have its top floor fully covered with a structural steel roof. This 300,000 square foot (2,000 ton) roof serves as both the structural and visual facade for the entry-exit of the facility. This portion of the project required very large and deep fabricated trusses that pushed the limit of the largest galvanizing baths in the area. Underscoring the importance of large dimensional capacity in galvanizing plants is the fact this project would not have been galvanized without that local large bath availability.

The roof structure not only provides protection from inclement weather for motorists using the top level it also keeps the deck dry precluding the need for regular corrosive de-icing operations. Additionally, 400 tons of hot-dip galvanized reinforcing bar was used to protect the concrete ramps and approaches from the road salt saturated traffic entering the parking structure.

The specifying engineers drew on their successful past experiences with galvanizing. Also, the architects liked the clean industrial look of galvanized steel for this project, contrasting nicely with the dour concrete components. For the countless thousands everyday who will travel to places unknown all over the world, this parking structure represents the completion of the first leg of each and every one of those voyages.

The brutally high usage levels and the classic winter road corrosion conditions challenge any construction design. The incomparable cost-benefit portfolio of HDG seems almost tailor-made for challenging applications like this. Easily specified, quickly processed and its inside and out durability against both time and abrasion is unmatched in its price range.

Hot-dip galvanizing's contribution to the long term durability of this structure is self evident, but HDG also contributes to the construction process itself with consistent factory controlled quality, rapid and reliable turnaround thanks to many high capacity plants to serve the demand as well as large bath dimensions that simplify and expand design considerations.

This parking structure was the first step in a $2.5 billion dollar reinvention of Montreal Airport over the next decade as it expands and modernizes every aspect of its facilities. Having this high-profile example of the amazingly compelling performance and value equation of hot-dip galvanized steel is critical for our even greater participation in every future step in this ongoing mega-project to reinvent Montreal Airport.

Details

Award Class

Newly Complete

Award Sectors

Building & Architecture

Environment

Industrial/Urban

Location

Montreal, QC Canada

Reasons for Galvanizing

Aesthetics, Coating Durability, Corrosion Performance, Life-Cycle Cost

Components Galvanized

All structural steel including joists, bracing, deck, roof structure and facades and more than 350 tons of rebar used in high risk areas of the concrete portion of the structure

Tonnage/Size

Steel: 2400

HDG: 2400

Team Members

Fabricators

Structures XL

Acier AGF

Engineer

SNC Lavalin

Owner

L’aéroport Montréal-Trudeau

Other

EBC INC.

Member Galvanizer(s)

Corbec - Montreal

Thank you! Your vote has been accepted.