Menu • Quick Links • Search

Login

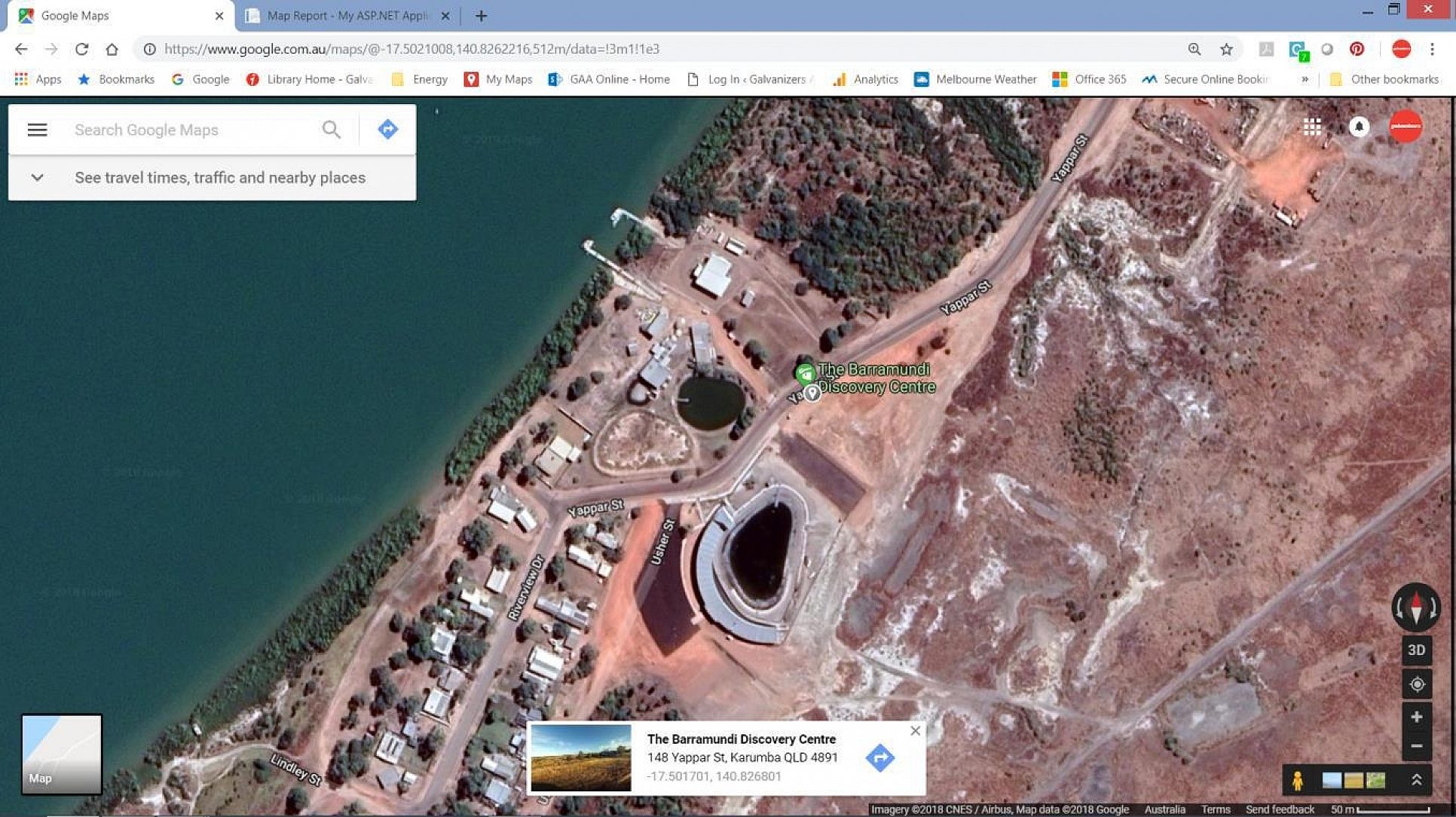

CloseDesigned by Brisbane-based practice Bud Brannigan Architects, the new Les Wilson Barramundi Discovery Centre offers an interpretive experience that will “tell the story of the southern gulf barramundi to visitors.” The 130-metre-long building is suspended a metre from the ground and takes the form of a linear arc, which wraps around a 2,500 square metre growing pond. The building increases in height from the southern to northern end, where a pitched-roof tower covers an external arrival and gathering verandah. The pond contains several thousand young barramundi from the hatchery. On the pond side of the building a continuous verandah, shaded by a perforated metal screen, provides external circulation and access to internal spaces and to outdoor pathways. Built at around $9.8m cost, the project was funded by a mixture of the Queensland Government Building Our Regions program, direct local council funding and other Queensland government sources.

The remoteness of the site also demanded the use of materials that could travel long distances by road with only minor damage – a factor critical to the use of hot dip galvanizing with its hard, abrasion resistant zinc-iron alloy layers.

The Les Wilson Barramundi Discovery Centre is made from 87 tonnes of (mostly) hot dip galvanized structural steel, 11,000 bolts and 50 tonnes of hardwood joists to form the floor frame. Hot dip galvanizing was used predominantly in the structural steel members (including tubular sections) and these are visible to the visitors to the centre. The Centre is located on the banks of the Norman River, approximately 4km inland from the Gulf of Carpentaria. While it is described by the council as a highly corrosive environment, the site is also remote, being about 2,200 km equidistant from both Darwin and Brisbane, or about 24 hours driving. The use of low maintenance materials was critical for the council and the designers. Obviously, the remoteness of the site also demanded the use of materials that could travel long distances by road with only minor damage – a factor critical to the use of hot dip galvanizing with its hard, abrasion resistant zinc-iron alloy layers. Also important was the compatibility of the preferred building materials, with the architect’s preference to use hardwood joists for longevity in the elevated underfloor areas which are susceptible to collection of airborne salts. Finally, the location experiences cyclonic activity. Although these have been somewhat rare (6 in the last 130 years), the area is classed by AS 1170.2 as Region C, cyclonic, with ultimate design wind speeds of 248 km/h and rainfall averaging over 800 mm per year. This meant the structure had to be a robust design, for which hot dip galvanized structural steel is a perfect fit.

The project maintains and adds to the high profile of hot dip galvanized steel projects in the ‘top end’ of Australia, in both functional and aesthetic applications. The project expands on the applications by providing a reference point for evidence in central Australia, but on the coast. It also increases the opportunity to showcase the transportability of galvanized steel - particularly to remote areas. The expansion will create a key environmental education resource for schools across Australia, and enhance the understanding of sustainable fishing, the unique Gulf environment and local cultural heritage values.

Details

Award Class

Newly Complete

Award Sectors

International

Environment

Tropical Marine

Location

Karumba, Australia

Reasons for Galvanizing

Coating Durability, Corrosion Performance, Quality of HDG

Components Galvanized

All structural steel

Tonnage/Size

Steel: 87

HDG: 87

Team Members

Owner

Carpentaria Shire Council

Fabricator

Wrens Construction

Architect

Bud Brannigan Architects

Member Galvanizer(s)

Valmont Coatings

Thank you! Your vote has been accepted.