Menu • Quick Links • Search

Login

CloseAs the longest undammed river in the contiguous United States, the Yellowstone River runs 692 miles from its source in Yellowstone National Park to its confluence with the Missouri River in North Dakota. Flowing northward, it traverses through picturesque landscapes of rugged canyons, lush valleys, and open plains. The river offers stunning views and opportunities for outdoor activities such as fishing, boating, and camping.

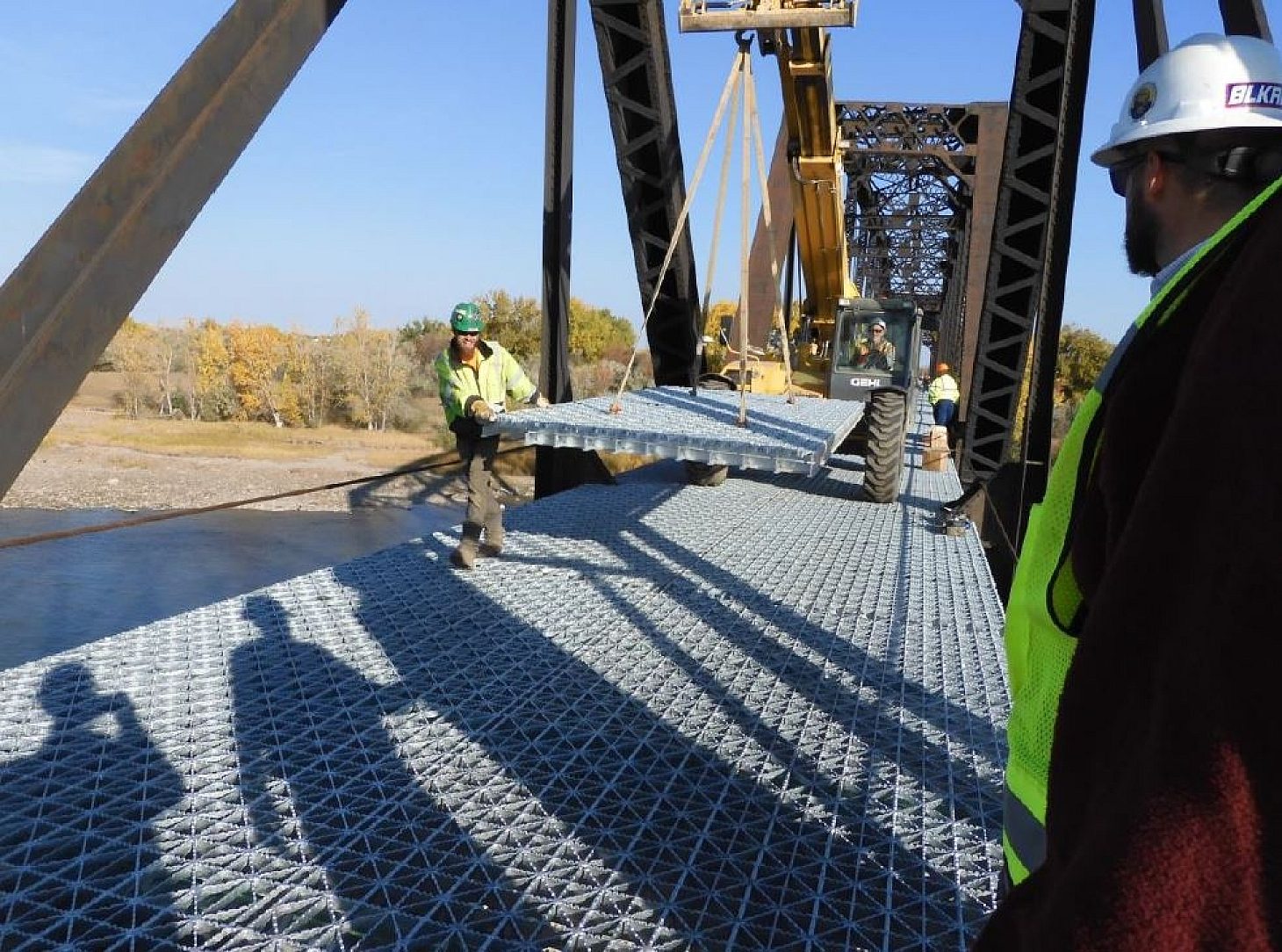

Hot-dip galvanized steel grid decks are relatively easy to retrofit or replace, making them a suitable choice for bridge rehabilitation projects. The ability to replace individual grid elements allows for cost-effective maintenance and extends the life of the bridge.

Situated just 9-miles North of Miles City, Montana, the historic 1,080 foot Kinsey Bridge has spanned the Yellowstone since 1907. Originally built as a single-track railroad bridge and abandoned by the railroad in 1980, it’s now used for residential, agricultural, and commercial traffic. By the end of 2022, the bridge had experienced substantial deterioration to its decking and was compromising safety and commerce in the area. Custer County officials identified this rehabilitation as a top priority for improving its transportation infrastructure.

Partnering with the Montana Department of Transportation and Forsgren Associates, Custer County officials awarded the project to Wadsworth Brothers and their affiliate fabricator and galvanizer. For this renovation, several options were considered including weathering steel and concrete designs. The county wanted to minimize its ongoing maintenance costs and address harsh winter weather de-icing concerns. Custer County, Montana has a semi-arid continental climate, with brutal snowy winters and unforgiving summers. Weathering steel is adversely affected by high levels of road salting without regular maintenance.. Corrosion rates are accelerated, and design strength is lessened. Concrete filled designs were expensive and impractical due to truss limitations.

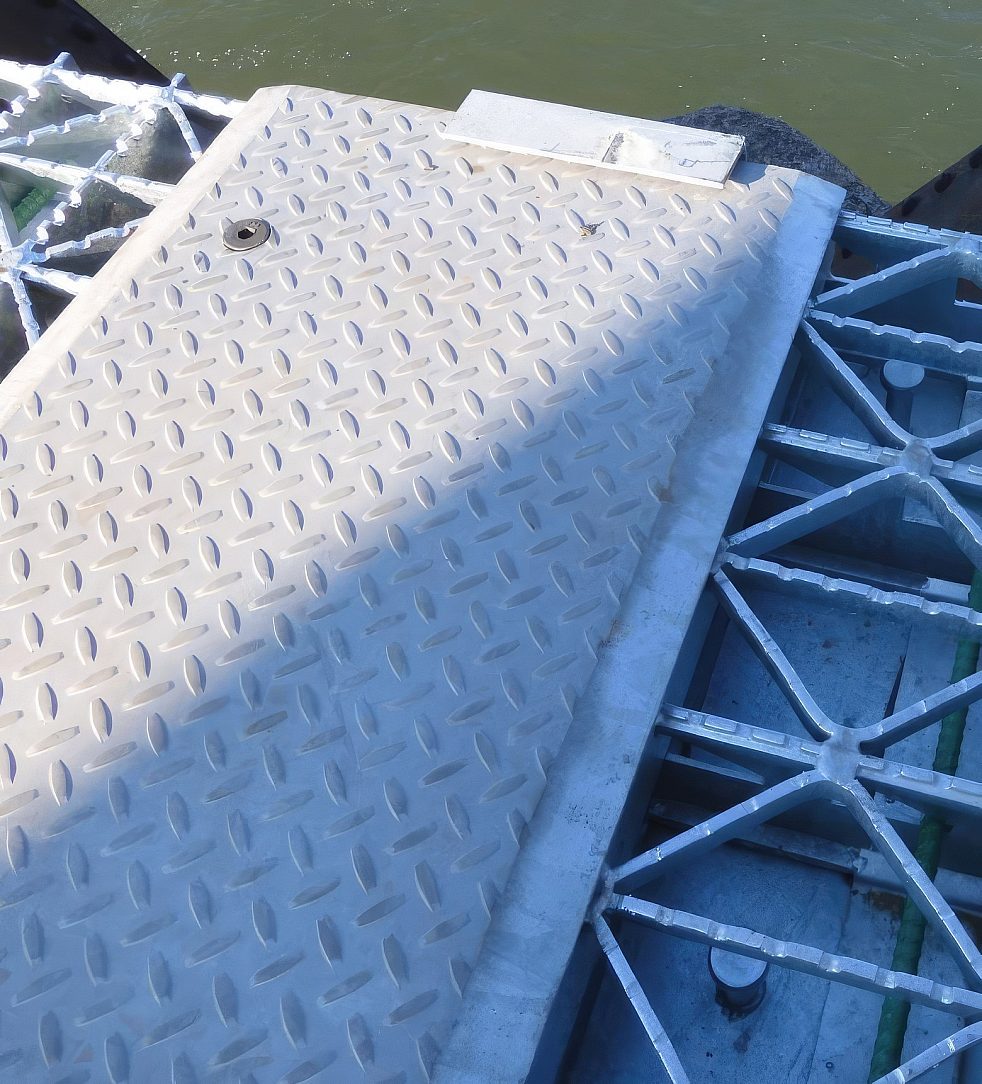

With this in mind, an intelligent decision was made to select a hot-dip galvanized open grid deck design, which provided a multitude of advantages in regard to construction costs, maintenance requirements and safety. Galvanized steel grid decks are relatively easy to retrofit or replace, making them a suitable choice for bridge rehabilitation projects. The ability to replace individual grid elements allows for cost-effective maintenance and extends the life of the bridge.

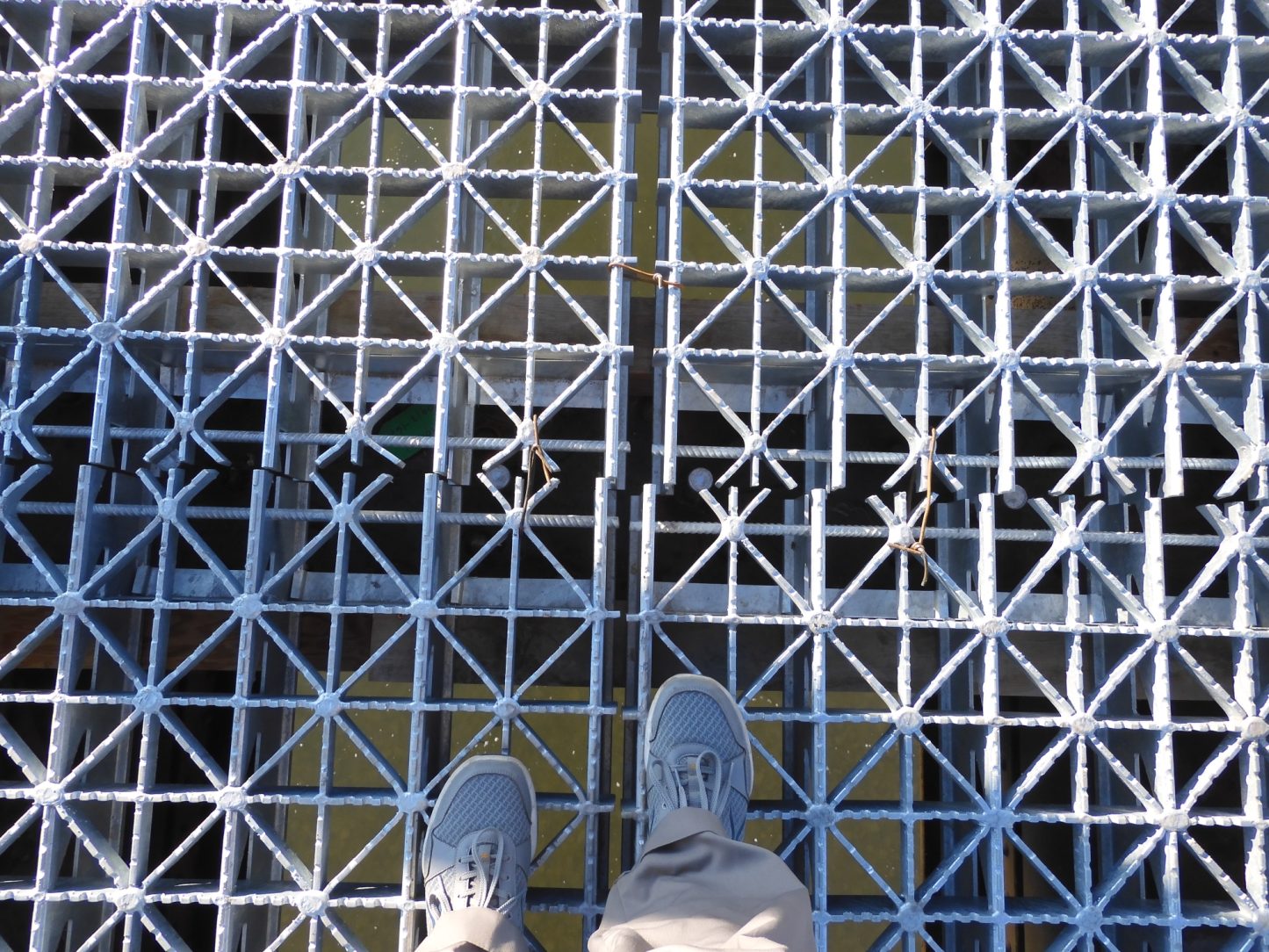

Galvanized open grid decks are relatively lightweight compared to solid decks made of concrete or other materials. This characteristic reduces the overall dead load on the bridge, making it more cost-effective and allowing for lighter structural support components. Galvanized decks boast an aesthetically pleasing appearance, marked by a zinc patina that facilitates creative and innovative bridge designs. This quality allows them to harmonize seamlessly with their surroundings, especially amid picturesque landscapes like Montana's scenic environment.

The open grid design also allows for efficient drainage of rainwater and snowmelt. Debris can fall through the gaps, reducing the risk of ponding and improving the safety of the bridge. Coupled with the use of galvanized steel, proper drainage and natural ventilation help reduce the contact time between moisture and steel, further minimizing the risk of corrosion to the structure.

Construction consisted of the removal of the old decking, installation of new galvanized floor beams, deck panels, expansion joint plates, and railing. This design doesn’t require a drainage system, will not easily ice over, and will require minimal maintenance over the long service life of the bridge. The decision to remove knee bracing from the final design increased the usable width from 12’4” to 15’ 2”.

Since the construction completed in early 2023 the bridge has been reopened, connecting the 9,000 residents of Miles City, Montana to the rest of Custer County for many years to come. Thanks to the selection of galvanized steel design, the area will benefit from increased safety, lower installation and maintenance costs and an aesthetically pleasing design for decades to come!

Details

Award Class

Newly Complete

Award Sectors

Bridge & Highway

Environment

Rural

Location

Miles City, MT United States

Reasons for Galvanizing

Aesthetics, Coating Durability, Corrosion Performance, Initial Cost, Life-Cycle Cost

Components Galvanized

Bridge Decking, Floor Beams, Railing, and Expansion Plates

Tonnage/Size

Steel: 150

HDG: 150

Team Members

Owner

Montana Department of Transportation

Fabricator

Frontier Gratings

Specifiers

Forsgren Associates Inc

Wadsworth Brothers

Other

Miles City Construction

Member Galvanizer(s)

AZZ Galvanizing - Nashville

Thank you! Your vote has been accepted.