Menu • Quick Links • Search

Login

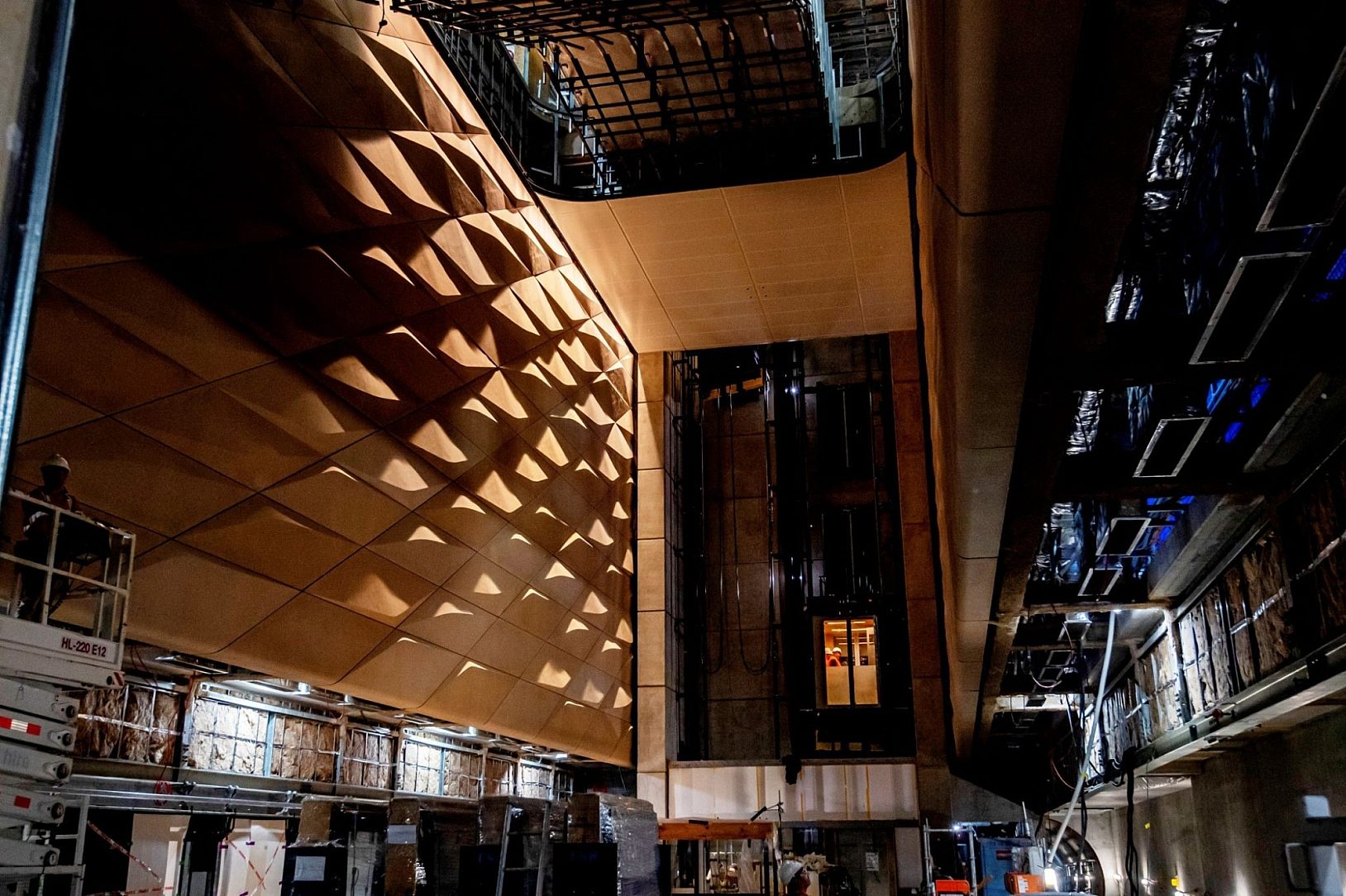

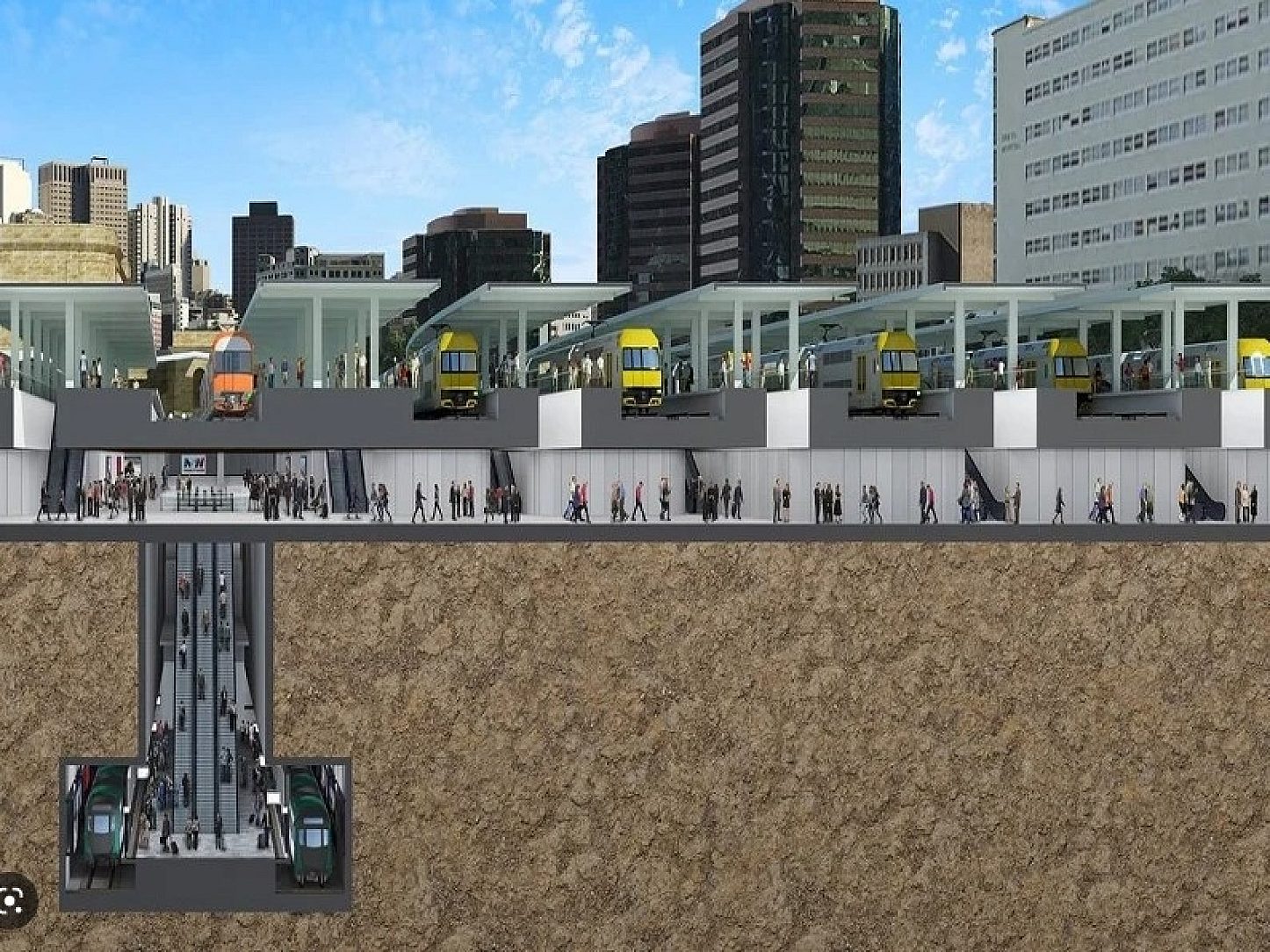

CloseIt all started in the heart of Sydney where a monumental transformation was underway. The primary focus, the Central Station Sydney, Metro project, a $955 million endeavor, aimed to revitalize and expand Australia's busiest commuter hub. This ambitious infrastructure upgrade included the construction of new metro platforms beneath the station and the creation of Central Walk, a sprawling underground pedestrian concourse connecting passengers to trains, light rail, and the new Sydney Metro platforms.

Longevity is imperative, the design life of our product is 100 years plus.

The magnitude of the project was staggering, with the bustling Central Station serving as the epicenter of Sydney's public transportation network. Prior to the COVID-19 pandemic, over 270,000 people passed through Central Station daily, a number projected to skyrocket to 450,000 within the next two decades. To meet this growing demand and ensure the project's longevity, every aspect had to be strategically planned and executed.

With a design lifespan of 100 years, the choice of coating was paramount. It had to provide not only durability but also ease of maintenance and minimal environmental impact. Hot-dip galvanizing was able to deliver long-lasting durability which decreases the environmental impact by eliminating maintenance.

The massive project located in the heart of Sydney during ongoing operation of the bustling station led to a number of challenges. As with any project of this magnitude, design changes were inevitable, but hot-dip galvanizing’s quick turnaround proved to be essential – particularly when structural steelwork required stripping and re-galvanizing to accommodate these modifications. Furthermore, the galvanizer was able to store finished items at their facility and adjust schedules to meet site demand without compromising the coating during the rigors of transport which can be common with other coatings,

The station’s central location and ongoing operations presented its own set of formidable challenges, from traffic congestion to access difficulties. Installation had to align with the station’s bustling activity, and delays were not an option as they would disrupt the station’s daily routine Hot-dip galvanizing’s speed and efficiency ensured materials were undamaged during transport and ready on time – keeping the project on track.

Throughout the project, teamwork and communication were crucial. Regular interactions between the galvanizer and the fabricator ensured that tight delivery schedules and project milestones were met. The galvanizer worked tirelessly, even implementing shift work, when necessary, to align with project expectations and meet the customer’s needs.

The benefits of choosing hot-dip galvanizing over other coating methods was simple. It not only provided the durability needed for a century-long project but also demonstrated its sustainability, producing minimal waste and offering the potential for infinite recyclability. To prove its strength, mil readings taken from the project were inserted into the American Galvanizers Association Zinc Coating Life Predictor. The results were staggering, showing that the project would endure a coating life well over 100 years into the future. The protective qualities and extended service life of galvanized steel made it the superior choice.

The Central Station Sydney Metro will continue to attract tourists and locals alike, drive market growth, enhance sustainability and promote the galvanizing industry on a global scale.

Details

Award Class

Newly Complete

Award Sectors

International

Environment

Industrial/Urban

Location

Sydney, Australia

Reasons for Galvanizing

Aesthetics, Coating Durability, Corrosion Performance, Life-Cycle Cost, Quality of HDG, Sustainability, Turnaround Time

Components Galvanized

Structural steel beams, columns, channels, angles, grid mesh

Tonnage/Size

Steel: 1200

HDG: 700

Team Members

Fabricators

John Mackenzie

Industrial Maintenance & Fabrications

Peter Thomson

Industrial Maintenance & Fabrications

Other

Laing O’Rourke

Member Galvanizer(s)

Valmont Coatings

Thank you! Your vote has been accepted.