Menu • Quick Links • Search

Login

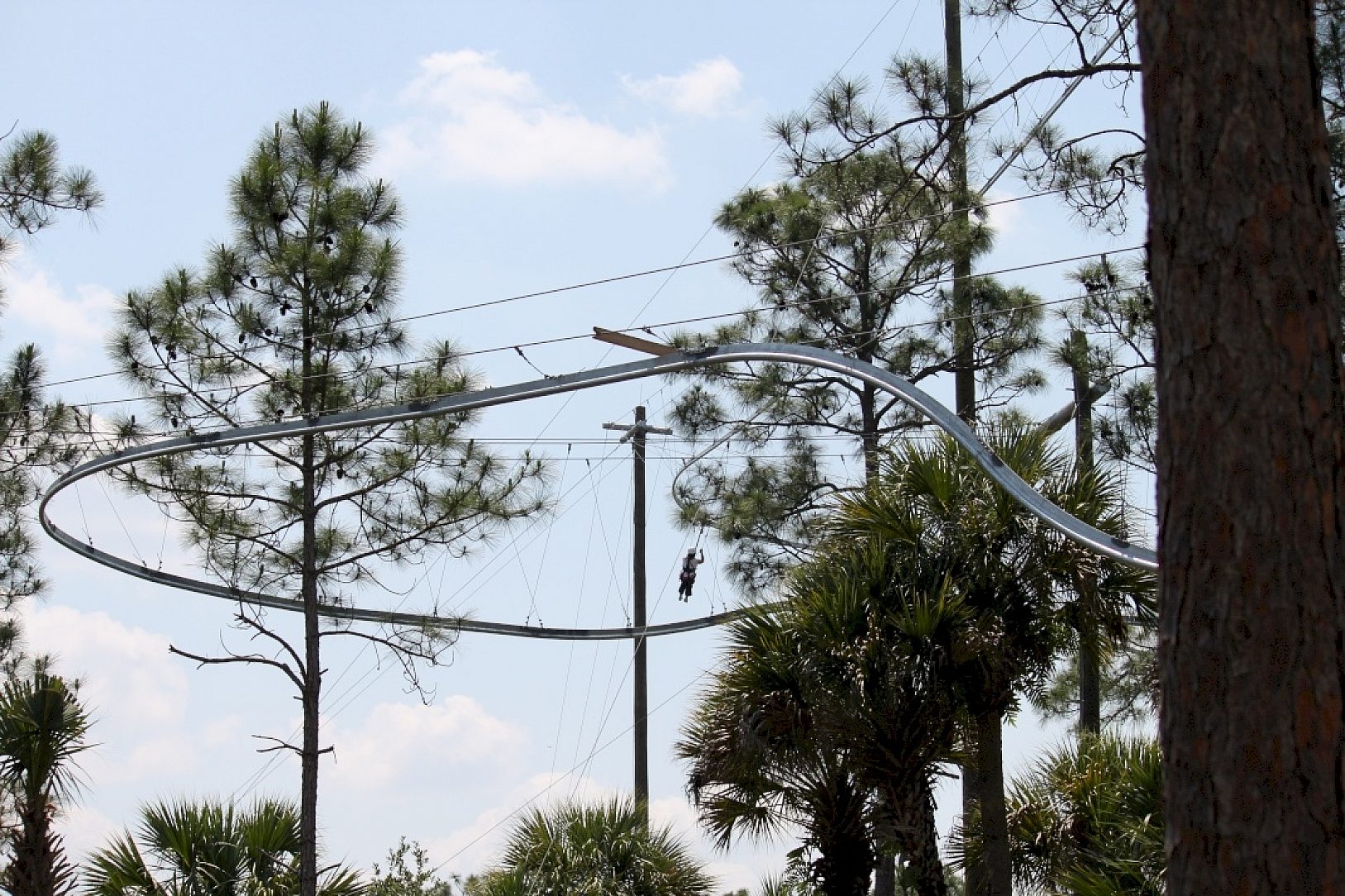

CloseEco Adventure Technologies unveiled the AvatarOne ride at Florida EcoSafaris, located in St. Cloud, Florida, on April 6, 2012. The Rattlesnake, which is the first installation of the system in the United States, is 1,000 feet long, 65 feet high and reaches speeds of 20 miles per hour, providing riders with the thrills of a zip line as well as the whipping turns and adrenaline-filled drops of a roller coaster. E.A.T.s creation is the only of its kind, and plans are in place for several other installations throughout the United States.

The AvatarOne has been rated by ASTM to guarantee riders safety for over 1 million ride cycles.

Among other challenges associated with the creation and design of a new product, E.A.T. faced the decision of how to protect the ride from the warm, humid and corrosive environment it is located in, as well as the wear and tear caused by the trolleys. Rider safety was the first priority during the design phase of production, and the structural integrity of the track and its components remaining intact was crucial. Chris Stanton, the designer for E.A.T., said, The first and most important [reason we chose hot-dip galvanizing] was for safety. This ride supports a life, and it is paramount the track not have a catastrophic failure. Without galvanizing, the pipe will begin to corrode from the inside out. The inside of the pipe cannot be inspected. In addition to the track itself, all brackets and fasteners were HDG. The AvatarOne has been rated by ASTM to guarantee riders safety for over 1 million ride cycles.

The superior abrasion resistance of a hot-dip galvanized coating, in addition to the longevity of the coating life and its ability to protect against corrosion, is unparalleled among competing coating systems. Initially, powder coating was specified to be the coating for the ride, but problems immediately arose. The powder coated prototype track received an enormous amount of damage during installation. The galvanized coating does not show any wear during that process, Stanton said. Quality characteristics such as these allow E.A.T. to market the AvatarOne as a reliable, low-maintenance product, and HDG is now used exclusively for the track and its components. As a result of their confidence in its performance, they now specify HDG for other recreational attractions.

The AvatarOne was originally designed to be in harmony with nature and is advertised as eco-friendly because it requires no energy usage to power the ride. Likewise, the coating on the ride contains no toxins or harmful chemicals only one of earths most abundant, naturally-occurring elements. The HDG coatings appearance also provides some peace of mind for riders. The benefit is that it appears more solid and sturdy to the average Joe, Stanton said. Furthermore, the purpose of the ride is to provide a thrilling adventure through natures raw, unaltered beauty. The subtle appearance of the AvatarOnes galvanized track and hardware does not distract from the environment, but merely serves as a vehicle by which to fully experience it.

Details

Year Galvanized

2012

Award Class

Newly Complete

Award Sectors

Recreation & Entertainment

Environment

Tropical Marine

Location

St. Cloud, FL United States

Reasons for Galvanizing

Coating Durability, Corrosion Performance, Quality of HDG, Sustainability

Components Galvanized

Monorail pipe, brackets, support columns, and fasteners.

Tonnage/Size

Steel: 100

HDG: 100

Team Members

Engineer

Chris Stanton

EcoAdventure Technologies

Fabricator

John Orth

Go Industries

Member Galvanizer(s)

AZZ Galvanizing - Hurst

Thank you! Your vote has been accepted.