Moving Parts

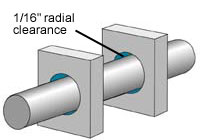

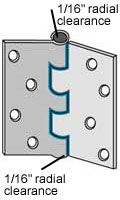

When a galvanized assembly incorporates moving parts (such as drop-handles, shackles, and shafts), a radial clearance of not less than 1/16-inch (1.5 mm) must be allowed to ensure full freedom of movement after the addition of zinc during galvanizing. Whenever possible, work should be designed so that hinges can be bolted to frames, covers, bodies, and other items after galvanizing.

Hinges should be galvanized separately and assembled after galvanizing. All hinges to be galvanized should be of the loose-pin type. Before galvanizing, any adjacent edges should be ground to give at least 1/32-inch (0.8 mm) clearance. The pin holes can be cleared of excess zinc during assembly. After hinges are galvanized, it is recommended an undersized pin be used to compensate for the zinc picked up during galvanizing. If desired, the pin holes in the hinges may be reamed 1/32-inch (0.8 mm) after galvanizing to permit the use of regular-size pins. On hinges, all adjacent surfaces must be ground 1/32-inch (0.8 mm) on both pieces to allow for thickness increases. Grinding both pieces is necessary.

At times, moving parts must be reheated in order for them to work freely. Although heating may cause discoloration of the galvanized coating near the reheated area, this discoloration does not affect the corrosion protection of the galvanized surface.